Low shrinkage epoxy resin adhesives are specialized adhesives that offer a range of benefits in various industrial applications. These adhesives are formulated to minimize the dimensional changes that typically occur during the curing process, making them ideal for use in environments where precision and stability are crucial. Understanding the properties and applications of low shrinkage epoxy resin adhesives can help manufacturers select the right adhesive solutions for their projects.

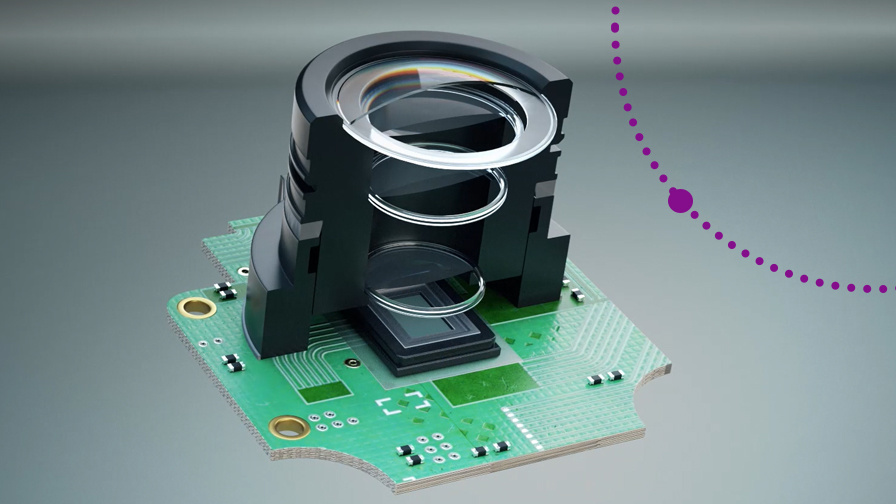

One of the primary advantages of low shrinkage epoxy resin adhesives is their ability to maintain dimensional stability. Traditional epoxies often experience shrinkage as they cure, which can lead to misalignment and weak bonds in critical assemblies. Low shrinkage formulations are designed to counteract this issue, ensuring that components remain properly aligned during and after the curing process. This is particularly important in industries such as aerospace, automotive, and electronics, where even the slightest misalignment can result in significant performance issues.

In addition to their low shrinkage properties, these adhesives exhibit excellent chemical resistance and mechanical strength. They are capable of bonding a wide variety of substrates, including metals, plastics, and composites. This versatility makes them suitable for a range of applications, from structural bonding in construction to intricate electronic assembly. The ability to bond different materials reliably and securely is a significant advantage in modern manufacturing, where multi-material products are increasingly common.

Low shrinkage epoxy resin adhesives also offer enhanced thermal stability, enabling them to maintain performance under varying temperature conditions. This characteristic is vital for applications that experience thermal cycles, such as automotive or aerospace components. Additionally, their excellent electrical insulating properties make them suitable for use in electronic devices, where insulation from electrical currents is essential.

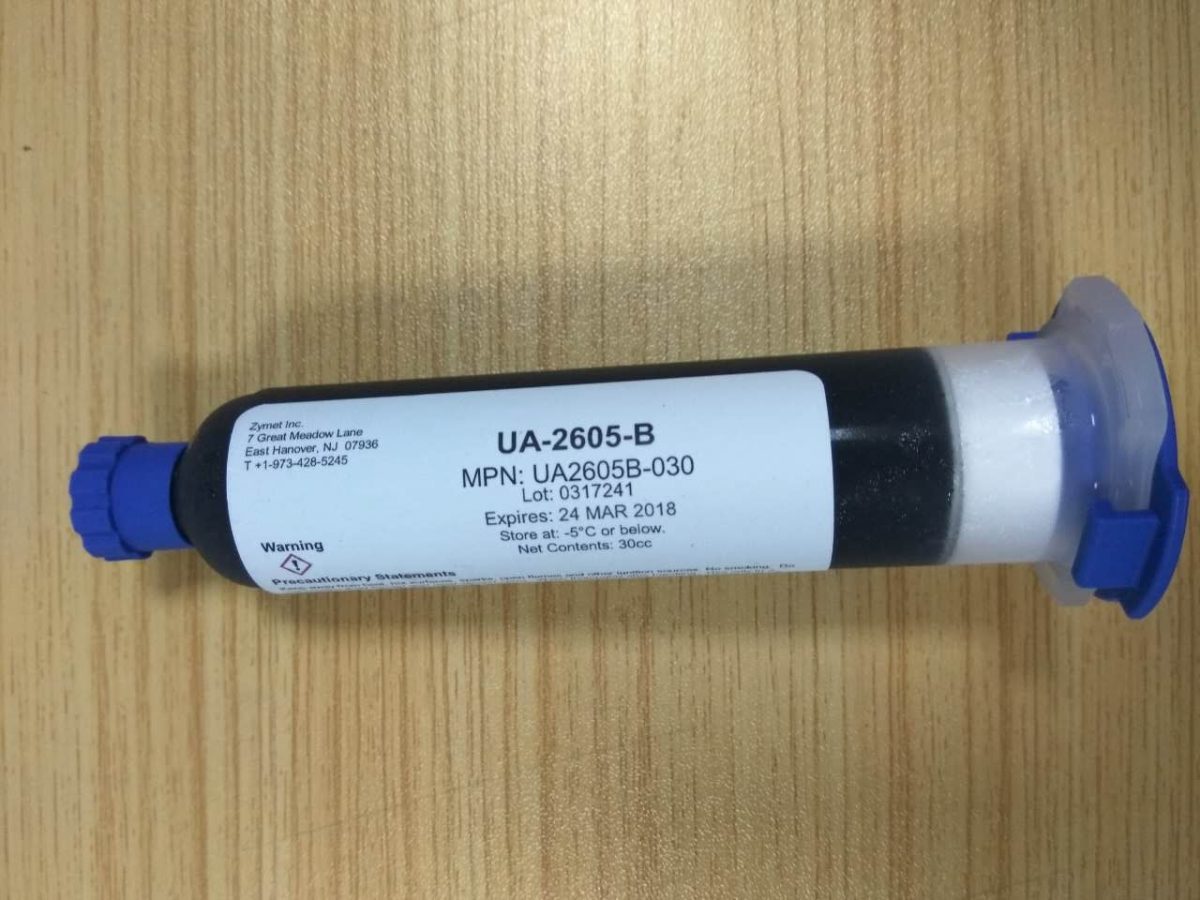

The curing process of low shrinkage epoxy resin adhesives can be tailored to meet specific requirements, including curing time and temperature. This customization allows manufacturers to optimize the adhesive for their particular applications, ensuring that it meets the necessary performance standards without compromising on efficiency.

When selecting low shrinkage epoxy resin adhesives, it is essential to consider factors such as the substrates being bonded, the environmental conditions they will face, and the desired curing characteristics. By understanding these variables, manufacturers can make informed decisions that lead to enhanced product reliability and performance.

In conclusion, low shrinkage epoxy resin adhesives are invaluable in today's manufacturing landscape, offering numerous benefits such as dimensional stability, chemical resistance, and mechanical strength. Their ability to bond diverse materials while maintaining performance under various conditions makes them a go-to solution for many industries. Whether you are involved in construction, automotive, or electronics, understanding and utilizing low shrinkage epoxy resin adhesives can lead to improved product quality and operational efficiency.

One of the primary advantages of low shrinkage epoxy resin adhesives is their ability to maintain dimensional stability. Traditional epoxies often experience shrinkage as they cure, which can lead to misalignment and weak bonds in critical assemblies. Low shrinkage formulations are designed to counteract this issue, ensuring that components remain properly aligned during and after the curing process. This is particularly important in industries such as aerospace, automotive, and electronics, where even the slightest misalignment can result in significant performance issues.

In addition to their low shrinkage properties, these adhesives exhibit excellent chemical resistance and mechanical strength. They are capable of bonding a wide variety of substrates, including metals, plastics, and composites. This versatility makes them suitable for a range of applications, from structural bonding in construction to intricate electronic assembly. The ability to bond different materials reliably and securely is a significant advantage in modern manufacturing, where multi-material products are increasingly common.

Low shrinkage epoxy resin adhesives also offer enhanced thermal stability, enabling them to maintain performance under varying temperature conditions. This characteristic is vital for applications that experience thermal cycles, such as automotive or aerospace components. Additionally, their excellent electrical insulating properties make them suitable for use in electronic devices, where insulation from electrical currents is essential.

The curing process of low shrinkage epoxy resin adhesives can be tailored to meet specific requirements, including curing time and temperature. This customization allows manufacturers to optimize the adhesive for their particular applications, ensuring that it meets the necessary performance standards without compromising on efficiency.

When selecting low shrinkage epoxy resin adhesives, it is essential to consider factors such as the substrates being bonded, the environmental conditions they will face, and the desired curing characteristics. By understanding these variables, manufacturers can make informed decisions that lead to enhanced product reliability and performance.

In conclusion, low shrinkage epoxy resin adhesives are invaluable in today's manufacturing landscape, offering numerous benefits such as dimensional stability, chemical resistance, and mechanical strength. Their ability to bond diverse materials while maintaining performance under various conditions makes them a go-to solution for many industries. Whether you are involved in construction, automotive, or electronics, understanding and utilizing low shrinkage epoxy resin adhesives can lead to improved product quality and operational efficiency.

Related Information

China:+86 13509643690

China:+86 13509643690