Expert Recommendations for Using Repairable Black Adhesive Effectively

In the world of adhesive technologies, repairable black adhesive stands out due to its versatility and effectiveness across various applications. Whether you’re involved in industrial manufacturing, DIY projects, or crafting, knowing how to use this type of adhesive correctly can save time and ensure strong, reliable bonds. This article provides comprehensive tips to help you utilize repairable black adhesive effectively, maximizing its potential for your specific needs.

Table of Contents

- 1. Understanding Repairable Black Adhesive

- 2. Applications of Repairable Black Adhesive

- 3. Key Advantages of Repairable Black Adhesive

- 4. Proper Preparation Techniques

- 5. Application Methods for Repairable Black Adhesive

- 6. Curing and Drying Process

- 7. Troubleshooting Common Issues

- 8. Safety Considerations When Using Adhesives

- 9. Conclusion

- 10. FAQs

1. Understanding Repairable Black Adhesive

Repairable black adhesive is a specialized bonding agent formulated to provide strong adhesion while allowing for adjustments or removals post-application. This adhesive is particularly useful in scenarios where temporary bonds are needed or when repairs are anticipated. Its black color often offers aesthetic appeal in applications where visible adhesive lines may be a concern.

What Makes It Unique?

This adhesive is made from a combination of synthetic polymers and fillers, which gives it its unique properties. The repairable aspect refers to its ability to maintain adhesion while allowing for reworking, making it perfect for applications that may require adjustments.

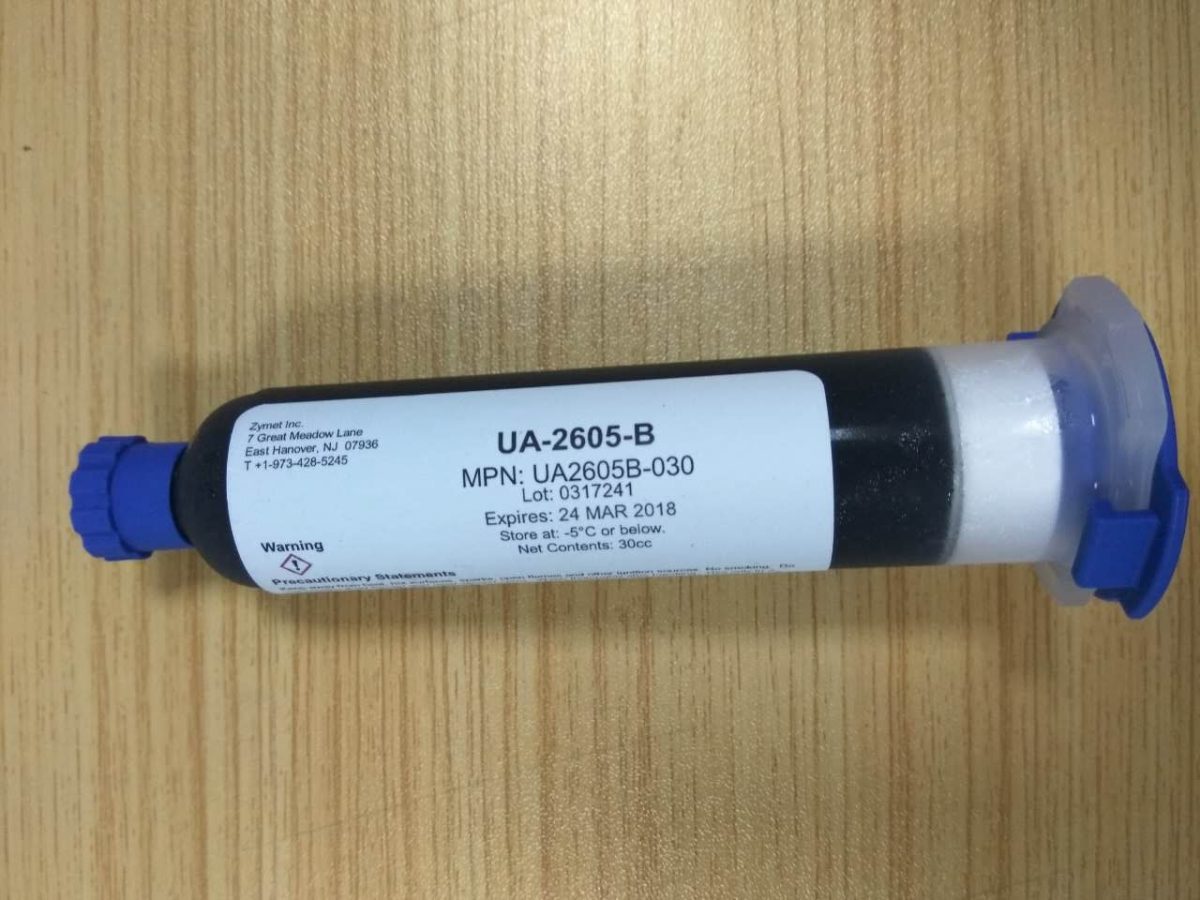

Types of Repairable Black Adhesives

There are various formulations available, including those designed for specific materials such as plastics, metals, and wood. Understanding which type suits your project best is essential for achieving optimal results.

2. Applications of Repairable Black Adhesive

The versatility of repairable black adhesive makes it suitable for numerous applications across different sectors.

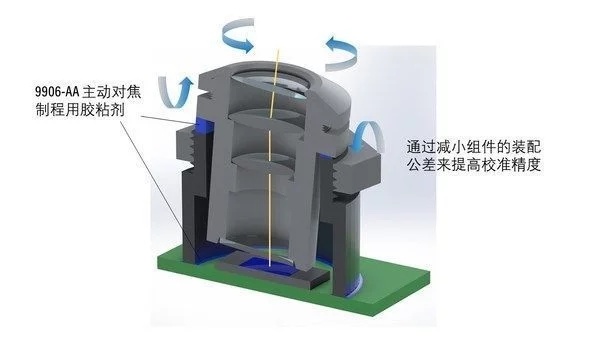

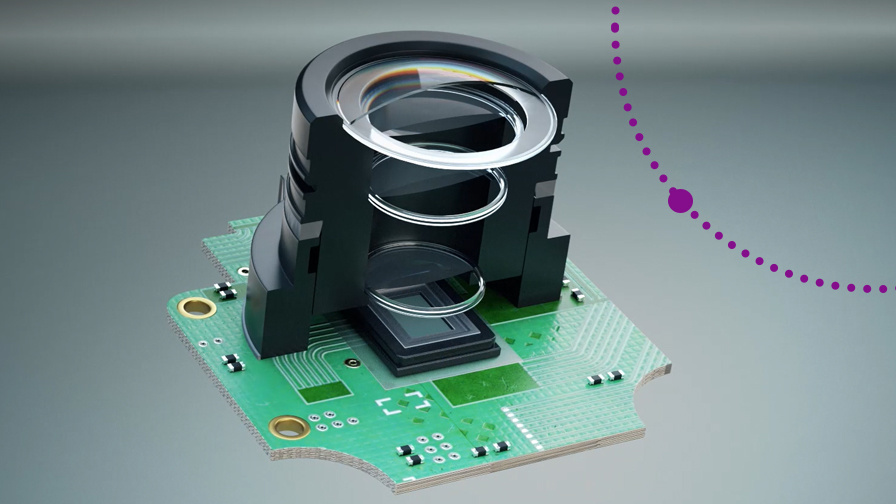

Industrial Use

In industrial settings, this adhesive is often used for bonding components in manufacturing processes, ensuring quick assembly and repair intervals.

DIY Projects

For DIY enthusiasts, repairable black adhesive is ideal for home repairs, crafting projects, and furniture assembly, allowing for clean finishes and easy adjustments.

Automotive Applications

In the automotive industry, it serves as an effective bonding solution for trims, interior fittings, and even some exterior parts, where a strong yet reversible bond is required.

3. Key Advantages of Repairable Black Adhesive

Utilizing repairable black adhesive offers several significant advantages.

Flexibility

One of the most notable benefits is the flexibility it provides. Users can reposition items without compromising the bond's integrity, making it a perfect choice for projects requiring adjustments.

Durability

Once cured, it provides a strong and resilient bond that can withstand various environmental conditions, ensuring longevity in use.

Aesthetic Appeal

The black color helps conceal the adhesive line in many projects, providing a clean and professional finish that is often desired in high-visibility applications.

4. Proper Preparation Techniques

Before applying repairable black adhesive, proper surface preparation is crucial for achieving the best results.

Surface Cleaning

Ensure that the surfaces to be bonded are clean and free from dust, grease, or moisture. This can typically be achieved using isopropyl alcohol or a similar cleaning solution.

Surface Roughening

For enhanced adhesion, especially on smooth surfaces, consider roughening the area slightly with sandpaper or a similar abrasive material. This creates a better mechanical bond.

5. Application Methods for Repairable Black Adhesive

The method of application can significantly impact the effectiveness of the adhesive.

Using a Caulking Gun

A caulking gun allows for precise application, particularly in larger areas or industrial settings. Apply a consistent bead of adhesive along the intended bonding line.

Brush or Roller Application

For smaller projects, using a brush or roller can provide a more controlled application, ensuring an even spread across the surface.

Pipette Method

When working with delicate materials or small components, a pipette can help apply the adhesive in a precise manner, reducing waste and ensuring accuracy.

6. Curing and Drying Process

Understanding the curing and drying process is vital for ensuring optimal performance of the adhesive.

Ambient Conditions

Ensure that the environment is suitable for curing. Factors such as humidity and temperature can impact the drying time and effectiveness of the bond.

Timeframes

Most repairable black adhesives require a specific time to set before they reach full strength, usually indicated on the packaging. Avoid disturbing the bond during this initial setting period.

7. Troubleshooting Common Issues

Even with careful application, issues can arise. Here are some common problems and solutions.

Poor Bonding

If the adhesive does not bond effectively, check to ensure the surfaces were adequately prepared and cleaned. Reapply as needed after proper preparation.

Adhesive Oozing

Oozing can occur with excessive application. Use only the amount necessary, and consider using a tool to spread the adhesive evenly.

8. Safety Considerations When Using Adhesives

Safety should always be a priority when working with adhesives.

Personal Protective Equipment

Always wear appropriate personal protective equipment (PPE), such as gloves and goggles, to prevent skin and eye contact.

Ventilation

Ensure proper ventilation in your workspace, particularly when working with adhesives that emit fumes. This helps reduce inhalation risks and maintains a safe working environment.

9. Conclusion

Using repairable black adhesive effectively requires a solid understanding of its properties, preparation techniques, application methods, and safety precautions. By following the tips outlined in this guide, you can achieve optimal results for various projects, ensuring strong and durable bonds while maintaining the flexibility necessary for adjustments. Whether you are engaged in complex industrial applications or simple DIY projects, mastering the use of repairable black adhesive will empower you to tackle a wide array of tasks with confidence.

10. FAQs

What materials can repairable black adhesive bond?

Repairable black adhesive is effective on a variety of materials, including wood, metal, plastics, and ceramics. Always check the manufacturer’s specifications for compatibility.

How long does it take for repairable black adhesive to cure?

The curing time can vary based on environmental conditions and the specific product used, but generally, it takes anywhere from 24 hours to a few days to reach full strength.

Can I use repairable black adhesive outdoors?

Many formulations are designed for both indoor and outdoor use. However, it’s critical to verify that the specific adhesive is rated for outdoor applications.

Is repairable black adhesive waterproof?

Some types of repairable black adhesive are water-resistant or waterproof. Always refer to the product details to understand its capabilities.

How do I remove repairable black adhesive if needed?

To remove the adhesive, use a solvent recommended by the manufacturer or a gentle scraper. Always test a small area first to ensure it does not damage the underlying surface.

Related Information

China:+86 13509643690

China:+86 13509643690