Instant Adhesives: Bridging the Gap Between Plastic and Rubber Materials

Introduction to Instant Adhesives

Instant adhesives, commonly referred to as cyanoacrylates, have revolutionized the manufacturing and repair industries. These adhesives bond materials in seconds, making them a popular choice for both professionals and DIY enthusiasts. Among their many applications, one of the most significant is their ability to bond plastic and rubber materials—two materials that traditionally posed challenges for adhesive bonding due to their unique properties.

The Science Behind Instant Adhesives

Instant adhesives work through a chemical reaction that occurs when the adhesive is exposed to moisture in the air. This reaction causes the cyanoacrylate molecules to polymerize, creating a strong bond between the surfaces being joined. The strength of this bond makes instant adhesives a go-to solution for various applications, especially when working with plastics and rubbers.

Understanding Plastic and Rubber Characteristics

To appreciate the effectiveness of instant adhesives, it's essential to understand the characteristics of the materials being bonded.

Properties of Plastic

Plastics are synthetic materials characterized by their versatility, lightweight nature, and resistance to corrosion. They can be molded into different shapes, making them ideal for various applications, from packaging to automotive parts.

Properties of Rubber

Rubber, on the other hand, is known for its elasticity, resilience, and ability to withstand various temperatures and environmental conditions. These properties make rubber a preferred choice in manufacturing seals, tires, and other products requiring flexibility.

Challenges of Bonding Plastic and Rubber

While both plastics and rubber offer numerous benefits, their bonding can be challenging. The non-porous nature of plastics and the oily surface of rubber can hinder proper adhesion. However, instant adhesives have been formulated to tackle these challenges effectively.

The Advantages of Instant Adhesives for Plastic and Rubber Bonding

Using instant adhesives to bond plastic and rubber comes with several advantages:

1. Quick Curing Time

Instant adhesives cure within seconds, allowing for rapid assembly and reducing downtime in manufacturing processes. This is particularly beneficial in industries where time is of the essence.

2. Strong Bonding Strength

These adhesives provide a robust bond that can withstand tension, impact, and environmental factors. This durability is essential for applications where the bonded materials are subjected to stress.

3. Versatility

Instant adhesives can bond a wide range of plastics and rubber types, making them suitable for various applications, from automotive to electronics.

4. Easy Application

With user-friendly dispensing options, instant adhesives can be applied precisely, ensuring minimal mess and maximum efficiency.

5. Cost-Effective Solutions

The affordability and longevity of instant adhesives make them a cost-effective bonding solution compared to other methods, such as welding or mechanical fasteners.

Types of Instant Adhesives Suitable for Plastic and Rubber

Not all instant adhesives are created equal. Various formulations are designed to meet specific bonding needs:

1. General-Purpose Cyanoacrylates

These are versatile and can bond many materials, including common plastics like PVC and ABS, as well as rubber.

2. Specialty Formulations

Some adhesives are specifically engineered to bond challenging materials, such as silicone rubber or polyolefins, which might require additional surface preparation.

3. Flexible Instant Adhesives

Formulated to remain flexible after curing, these adhesives are ideal for applications where movement is expected, such as in rubber seals.

Optimal Surface Preparation for Better Bonding

The strength of the bond created by instant adhesives largely depends on the surface preparation of the materials being joined. Here are some tips for achieving optimal results:

1. Clean the Surfaces

Ensure that both plastic and rubber surfaces are clean and free of contaminants, such as dust, oil, or grease. Using isopropyl alcohol or acetone can help in achieving a clean surface.

2. Roughen the Surface

For better adhesion, lightly sand the surfaces to create micro-abrasions. This increases the surface area for the adhesive to bond effectively.

3. Apply the Adhesive Properly

Use a small amount of adhesive to avoid overflow and ensure precise application. Apply pressure on the surfaces for a few seconds to allow the adhesive to set.

Applications of Instant Adhesives in Various Industries

Instant adhesives find use across various industries, demonstrating their versatility and effectiveness:

1. Automotive Industry

In the automotive sector, instant adhesives are used for bonding trim, repairing rubber seals, and securing components in place. Their quick curing time reduces assembly line delays.

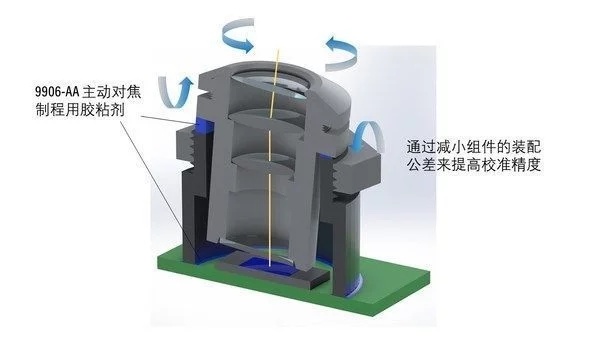

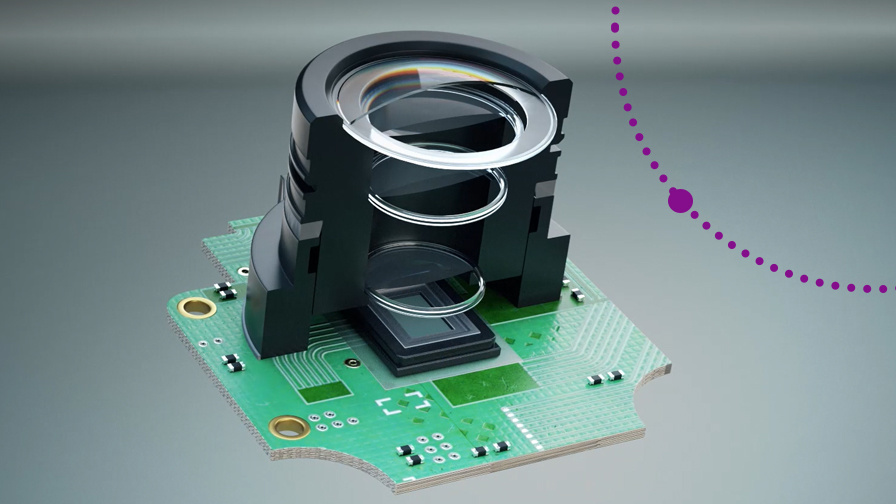

2. Electronics Manufacturing

Instant adhesives are employed in electronics for bonding components, securing wires, and encapsulating delicate parts. Their electrical insulation properties further enhance their utility in this sector.

3. Medical Devices

In the medical field, instant adhesives are used for bonding various materials in devices and packaging. Their rapid curing and biocompatibility make them ideal for such applications.

4. Consumer Products

From household items to recreational products, instant adhesives are commonly used for repairs and assembly, providing a quick solution for everyday bonding needs.

Safety Considerations When Using Instant Adhesives

While instant adhesives are generally safe to use, it’s essential to follow safety precautions to minimize risks:

1. Use in a Well-Ventilated Area

Ensure adequate ventilation when using instant adhesives to avoid inhalation of fumes.

2. Wear Protective Gear

Consider wearing gloves and safety goggles to protect your skin and eyes from accidental exposure to the adhesive.

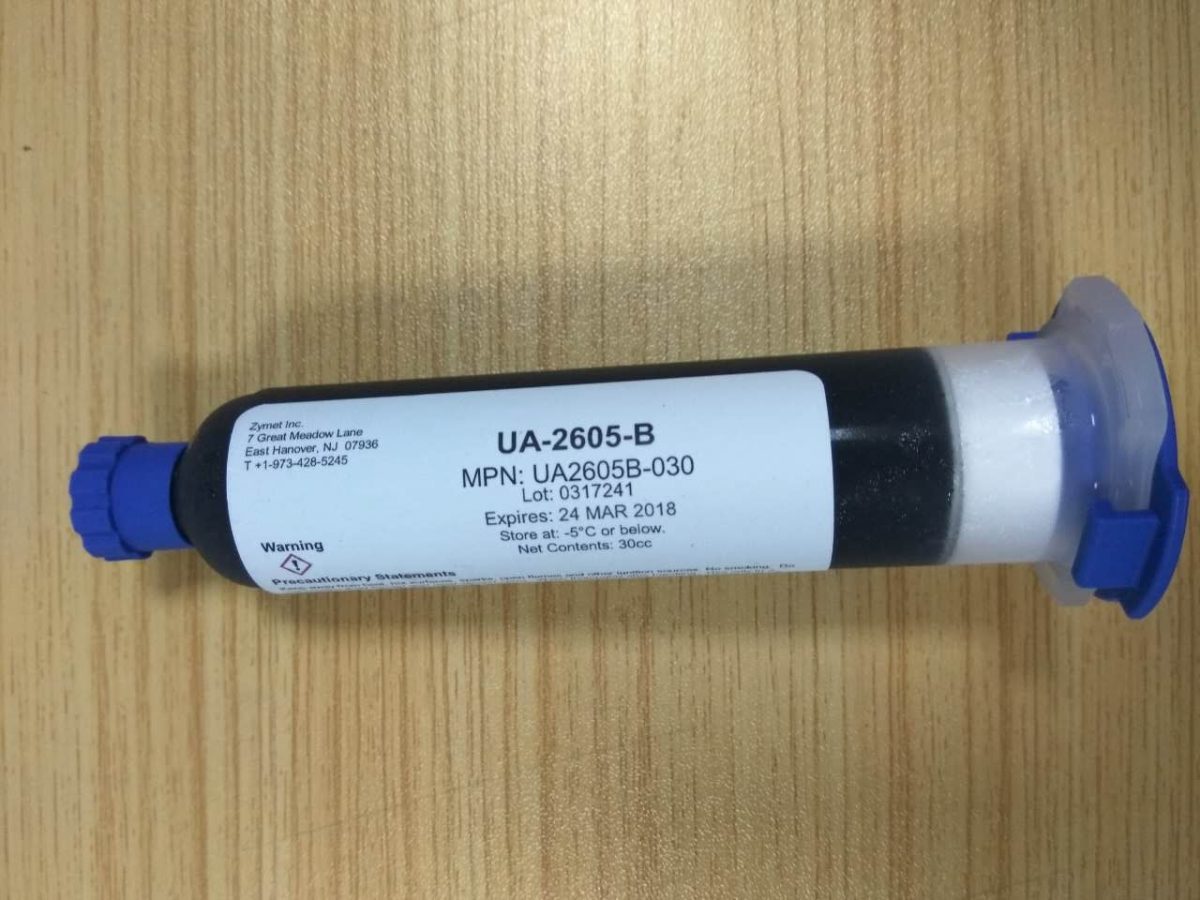

3. Store Properly

Keep instant adhesives in a cool, dry place, away from direct sunlight and humidity, to prolong their shelf life.

FAQs About Instant Adhesives for Plastic and Rubber

1. Can I use instant adhesives on all types of plastic and rubber?

Not all plastics and rubbers bond well. Check the adhesive specifications for compatibility with specific materials.

2. How long does it take for instant adhesives to cure?

Instant adhesives typically bond within seconds, but full curing can take up to 24 hours, depending on the adhesive and environmental conditions.

3. What should I do if I accidentally glue my fingers together?

Soak the bonded area in warm, soapy water and gently pry apart the fingers. If necessary, use acetone to dissolve the adhesive.

4. Are there any specific storage requirements for instant adhesives?

Store instant adhesives in a cool, dry place, and keep them tightly sealed to prevent moisture from affecting their performance.

5. Can instant adhesives be used for outdoor applications?

Yes, certain instant adhesives are formulated for outdoor use, but always check the product specifications for weather resistance.

Conclusion

Instant adhesives have become indispensable tools for bonding plastic and rubber materials across various industries. Their quick curing time, exceptional bonding strength, and versatility make them suitable for both professional applications and DIY projects. By understanding the characteristics of the materials involved and following proper surface preparation techniques, users can achieve optimal bonding results. With the right instant adhesive in hand, the challenges of working with plastic and rubber can be effortlessly overcome, leading to durable and reliable outcomes that stand the test of time.

Related Information

China:+86 13509643690

China:+86 13509643690