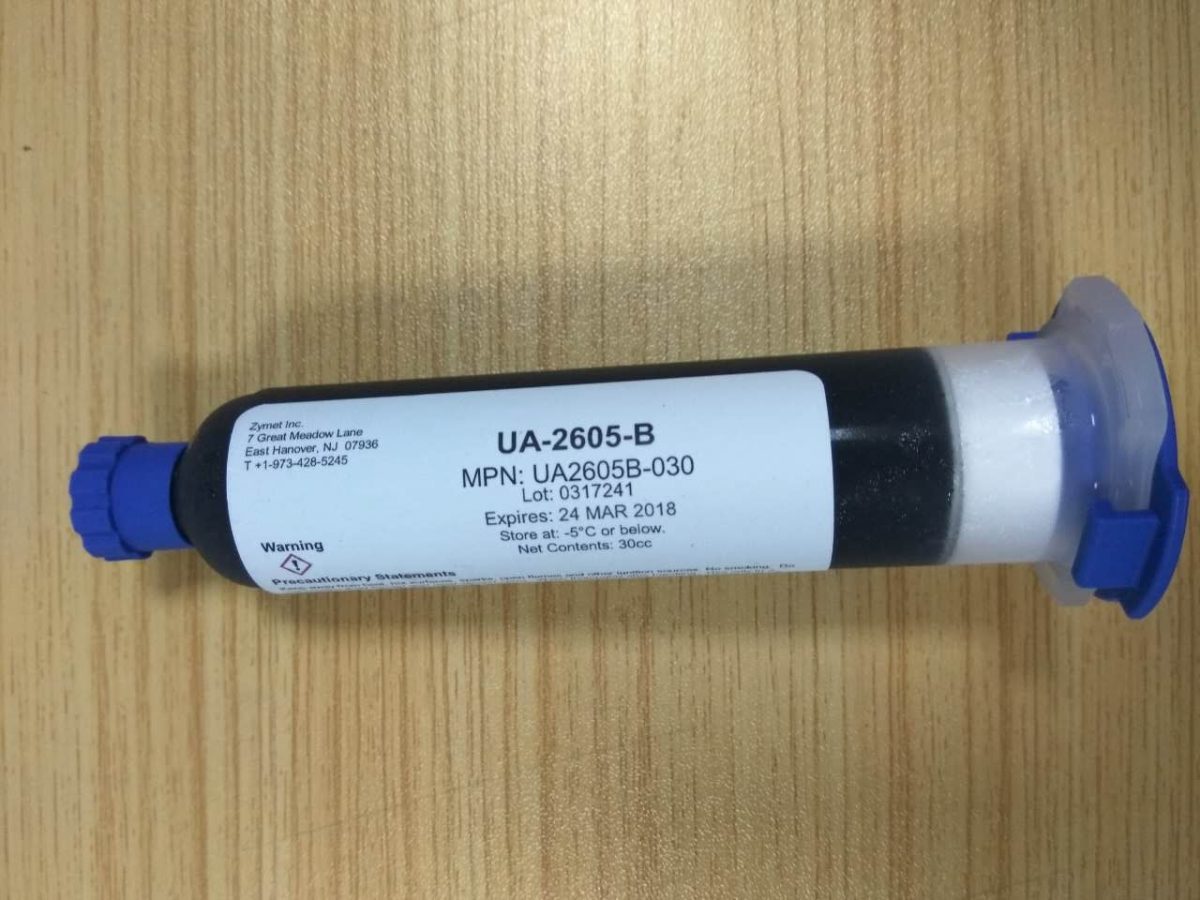

UV adhesives, or ultraviolet light-curable adhesives, are specially formulated compounds that cure and bond materials upon exposure to UV light. They are gaining popularity in the glass bonding industry due to their ability to create strong, durable bonds quickly and efficiently. Unlike traditional adhesives that rely on air exposure for curing, UV adhesives are activated by a specific wavelength of ultraviolet light, making them ideal for precise applications where clarity and bond strength are critical.

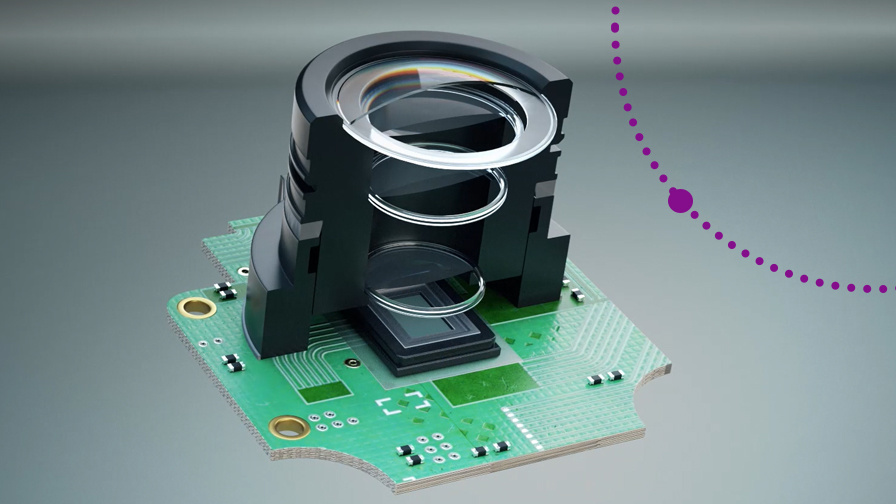

One of the primary advantages of UV adhesives for glass bonding is their clarity. When cured, UV adhesives remain transparent, which is essential for aesthetic applications such as glass furniture, displays, and decorative items. This property allows manufacturers to achieve seamless and clean joints that are nearly invisible, enhancing the overall appearance of the final product.

Another significant benefit of UV adhesives is their rapid curing time. Traditional adhesives may take hours or even days to reach full strength, while UV adhesives can cure in seconds when exposed to UV light. This rapid curing process not only speeds up production timelines but also improves workflow efficiency, making it a preferred choice in high-volume manufacturing environments.

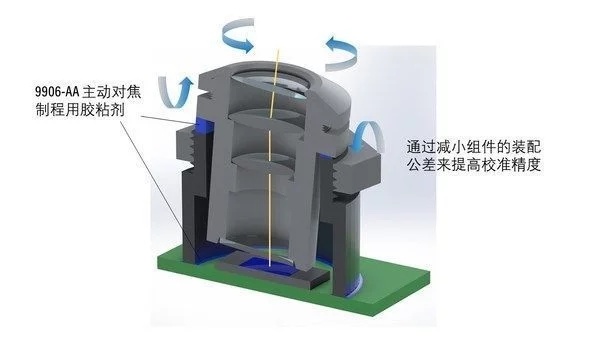

Furthermore, UV adhesives exhibit excellent adhesion to a variety of substrates, not just glass. They can bond to metals, plastics, ceramics, and even composites, making them versatile for various applications. This versatility is particularly advantageous in industries where multiple materials are often joined together, such as in electronics and automotive components.

However, it is essential to consider the environmental factors when using UV adhesives for glass bonding. Since they require UV light for curing, it is crucial to ensure that the curing process is adequately controlled to achieve the desired bond strength and performance. Additionally, the long-term durability of the bond should be assessed based on the specific environment in which the bonded glass will be used, including exposure to moisture, temperature fluctuations, and UV radiation.

In summary, UV adhesives for glass bonding represent an innovative solution in the adhesive market, offering quick curing times, clarity, and versatility. Their ability to create strong and virtually invisible bonds makes them an excellent choice for a wide range of glass applications. As industries continue to seek efficient and aesthetic bonding solutions, understanding the unique properties of UV adhesives will be essential for professionals looking to enhance their product offerings in the competitive market.

One of the primary advantages of UV adhesives for glass bonding is their clarity. When cured, UV adhesives remain transparent, which is essential for aesthetic applications such as glass furniture, displays, and decorative items. This property allows manufacturers to achieve seamless and clean joints that are nearly invisible, enhancing the overall appearance of the final product.

Another significant benefit of UV adhesives is their rapid curing time. Traditional adhesives may take hours or even days to reach full strength, while UV adhesives can cure in seconds when exposed to UV light. This rapid curing process not only speeds up production timelines but also improves workflow efficiency, making it a preferred choice in high-volume manufacturing environments.

Furthermore, UV adhesives exhibit excellent adhesion to a variety of substrates, not just glass. They can bond to metals, plastics, ceramics, and even composites, making them versatile for various applications. This versatility is particularly advantageous in industries where multiple materials are often joined together, such as in electronics and automotive components.

However, it is essential to consider the environmental factors when using UV adhesives for glass bonding. Since they require UV light for curing, it is crucial to ensure that the curing process is adequately controlled to achieve the desired bond strength and performance. Additionally, the long-term durability of the bond should be assessed based on the specific environment in which the bonded glass will be used, including exposure to moisture, temperature fluctuations, and UV radiation.

In summary, UV adhesives for glass bonding represent an innovative solution in the adhesive market, offering quick curing times, clarity, and versatility. Their ability to create strong and virtually invisible bonds makes them an excellent choice for a wide range of glass applications. As industries continue to seek efficient and aesthetic bonding solutions, understanding the unique properties of UV adhesives will be essential for professionals looking to enhance their product offerings in the competitive market.

Related Information

China:+86 13509643690

China:+86 13509643690