A Comprehensive Guide to Silicone Adhesive Sealants in Electronic Manufacturing

Table of Contents

- 1. Introduction to Silicone Adhesive Sealants

- 2. Benefits of Using Silicone Adhesive Sealants in Electronics

- 3. Types of Silicone Adhesive Sealants

- 4. Application Techniques for Silicone Adhesive Sealants

- 5. Environmental Considerations and Safety Precautions

- 6. Common Challenges and How to Overcome Them

- 7. Best Practices for Using Silicone Adhesive Sealants

- 8. Conclusion

- 9. FAQs

1. Introduction to Silicone Adhesive Sealants

Silicone adhesive sealants have become indispensable in the realm of electronic manufacturing. Their unique properties, including excellent temperature resistance, flexibility, and durability, make them ideal for various applications. These sealants are crucial in ensuring that electronic components are securely bonded, providing a protective barrier against moisture, dust, and other environmental factors.

In this guide, we will delve deep into the characteristics and applications of silicone adhesive sealants, paving the way for their optimal usage in electronic manufacturing processes.

2. Benefits of Using Silicone Adhesive Sealants in Electronics

Silicone adhesive sealants are not just versatile; they offer numerous advantages that enhance the reliability and quality of electronic products.

Durability and Longevity

One of the primary benefits of silicone sealants is their exceptional durability. They maintain their integrity over time, even under extreme temperatures and various environmental conditions. This longevity translates to reduced maintenance costs and increased product lifespan.

Excellent Adhesion Properties

Silicone adhesives offer strong adhesion to a wide range of substrates, including metals, glass, and plastics. This flexibility allows manufacturers to work with different materials without compromising the bond's strength.

Temperature Resistance

Silicone adhesive sealants can withstand a broad temperature range, typically from -60°C to over 200°C. This thermal stability makes them suitable for applications in high-heat environments, such as power supplies and circuit boards.

Moisture and Chemical Resistance

These sealants provide excellent protection against moisture and various chemicals, which is vital in preventing corrosion and degradation of electronic components.

Electrical Insulation

Silicone sealants are inherently non-conductive, making them an ideal choice for insulating electronic assemblies and preventing short circuits.

3. Types of Silicone Adhesive Sealants

Understanding the different types of silicone adhesive sealants available in the market is crucial for selecting the right product for your manufacturing needs.

General-Purpose Silicone Sealants

These sealants are widely used due to their versatility. They can bond various substrates and are suitable for indoor and outdoor applications.

High-Temperature Silicone Sealants

Designed to withstand extreme temperatures, these sealants are often employed in applications where heat exposure is a concern, such as automotive and aerospace industries.

Neutral-Cure Silicone Sealants

Neutral-cure silicone sealants release acetic acid during the curing process, making them less corrosive compared to acetoxy-cure types. They are suitable for sensitive materials and electronic applications.

Acetoxy-Cure Silicone Sealants

These sealants cure rapidly and provide excellent adhesion to non-porous surfaces. However, they can be corrosive to certain metals, so caution is required when using them in electronic applications.

Room Temperature Vulcanizing (RTV) Silicone Sealants

RTV silicone sealants are ideal for applications requiring flexibility and resistance to moisture. They cure at room temperature, making them easy to work with in various settings.

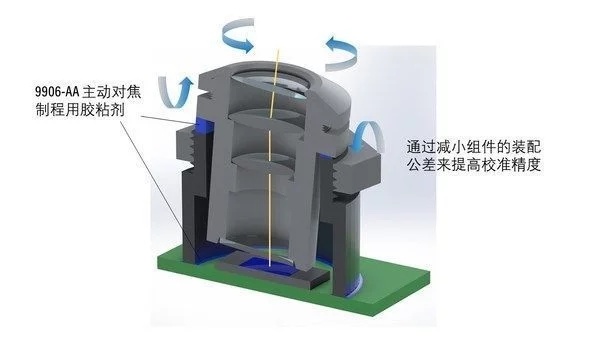

4. Application Techniques for Silicone Adhesive Sealants

Proper application techniques are vital for achieving optimal results with silicone adhesive sealants. Here are some best practices to ensure effective bonding:

Surface Preparation

Before applying silicone sealants, it's essential to prepare the surfaces. Clean them thoroughly to remove dust, grease, and contaminants that could hinder adhesion. Using isopropyl alcohol or a specialized cleaner can enhance surface cleanliness.

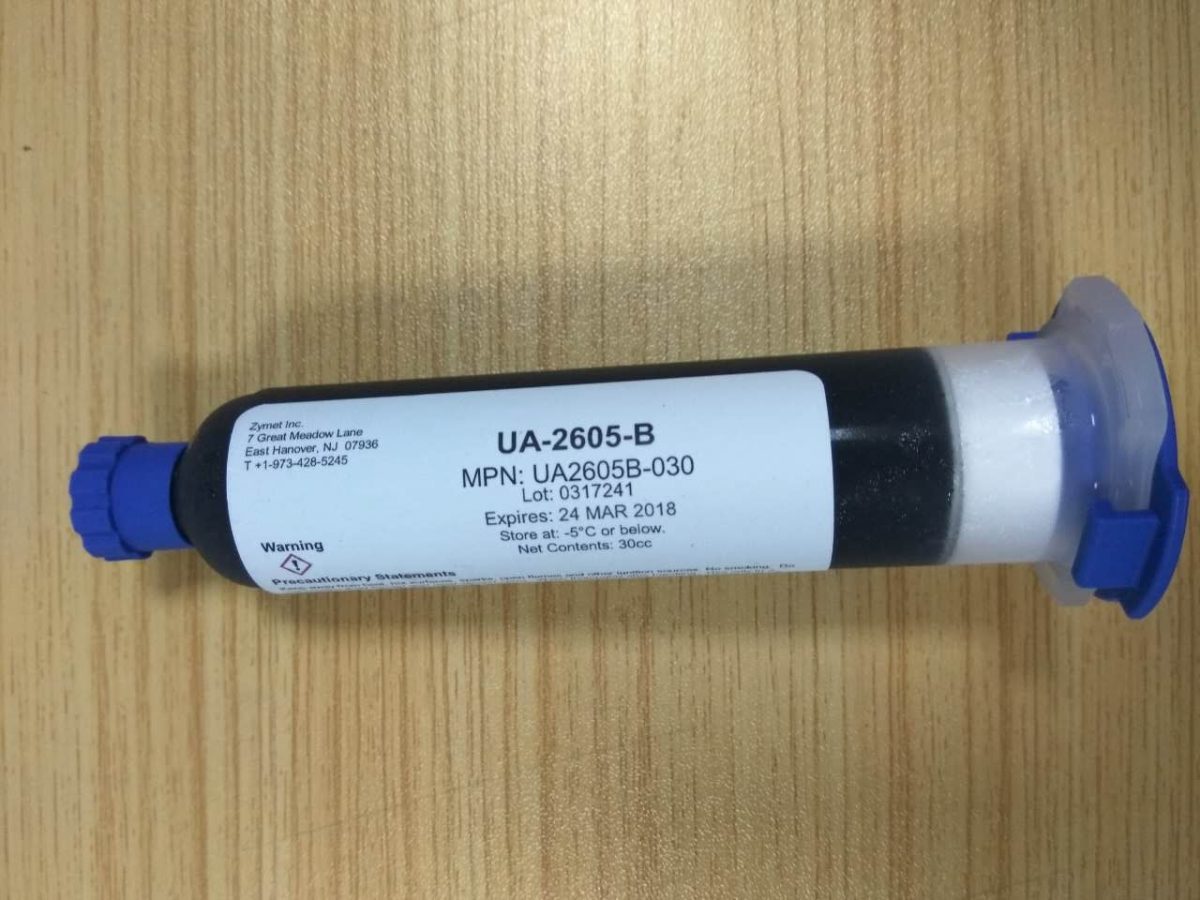

Proper Dispensing

Using a caulking gun or dispensing tool, apply the sealant evenly along the desired joint or bonding area. Maintaining a consistent bead of sealant will ensure an even distribution and strong bond.

Curing Time

Allow sufficient time for the silicone adhesive to cure fully. Depending on the type and environmental conditions, this can range from a few hours to several days. Consult the manufacturer's guidelines for specific curing times.

Temperature and Humidity Considerations

The performance of silicone sealants can be influenced by temperature and humidity levels during application. Ideally, apply sealants in moderate temperatures and low humidity for optimal curing.

5. Environmental Considerations and Safety Precautions

While silicone adhesive sealants are generally safe to use, it’s crucial to adhere to proper safety and environmental measures.

Personal Protective Equipment (PPE)

When working with silicone sealants, it is advisable to wear gloves, goggles, and masks to protect against potential irritation from fumes and skin contact.

Ventilation

Ensure adequate ventilation in working areas to disperse vapors released during the curing process. This practice minimizes exposure and enhances air quality.

Disposal of Waste

Dispose of any unused sealants and contaminated materials responsibly, following local regulations for hazardous waste disposal.

6. Common Challenges and How to Overcome Them

Despite their many advantages, silicone adhesive sealants can present certain challenges. Understanding these issues and knowing how to overcome them is essential for success.

Adhesion Failure

Inadequate surface preparation can lead to poor adhesion. To avoid this, always ensure that surfaces are clean and dry before application.

Curing Issues

Improper curing can result in weak bonds. Follow manufacturer's instructions regarding curing times and conditions to achieve optimal results.

Environmental Impact

Addressing the environmental impact of silicone sealants is important. Opt for low-VOC formulations to minimize harmful emissions and support eco-friendly practices.

7. Best Practices for Using Silicone Adhesive Sealants

Implementing best practices can significantly enhance the effectiveness of silicone adhesive sealants in electronic manufacturing.

Choosing the Right Sealant

Evaluate the specific requirements of your project to choose the most suitable type of silicone adhesive sealant. Consider factors such as temperature thresholds, substrate materials, and environmental conditions.

Consult Manufacturer Guidelines

Always refer to the manufacturer's data sheets for technical information, application instructions, and safety data to ensure optimal usage.

Testing and Quality Assurance

Conduct regular tests on the adhesion strength and durability of silicone sealants in your applications. Consistent quality checks help maintain high manufacturing standards.

8. Conclusion

Silicone adhesive sealants play a pivotal role in electronic manufacturing, providing essential bonding and protection for various applications. Their unique properties, such as durability, temperature resistance, and moisture protection, make them indispensable in producing reliable electronic devices. By understanding the types, benefits, and best practices associated with silicone adhesive sealants, manufacturers can enhance product quality and performance while maintaining safety and environmental awareness.

9. FAQs

1. What are silicone adhesive sealants made from?

Silicone adhesive sealants are typically made from silicone polymers, which provide flexibility and durability, along with various additives to enhance their performance.

2. Can silicone adhesive sealants be used on all surfaces?

While silicone adhesive sealants bond well to many surfaces, some may require specific formulations. Always check compatibility with your materials before application.

3. How long do silicone adhesive sealants take to cure?

Curing time varies based on the type of sealant and environmental conditions. Generally, it can range from a few hours to several days.

4. Are there any environmental concerns with silicone sealants?

Some silicone sealants may release volatile organic compounds (VOCs). Opting for low-VOC products can help mitigate environmental impact.

5. How do I clean up silicone adhesive sealants after application?

Uncured silicone sealants can be cleaned with mineral spirits or isopropyl alcohol. Once cured, removal may require mechanical means such as scraping or cutting.

Related Information

China:+86 13509643690

China:+86 13509643690