Choosing the Right UV Curing Adhesive for Your Electronic Projects: A Comprehensive Guide

Choosing the Right UV Curing Adhesive for Your Electronic Projects

In the fast-evolving world of electronics, the importance of selecting the right adhesive cannot be overstated. Particularly, UV curing adhesives have gained significant traction due to their rapid curing capabilities and excellent bonding properties. In this comprehensive guide, we will explore everything you need to know about choosing the right UV curing adhesive for your electronic projects, ensuring the success and longevity of your applications.

Table of Contents

- 1. Understanding UV Curing Adhesives

- 2. Advantages of UV Curing Adhesives in Electronics

- 3. Different Types of UV Curing Adhesives

- 4. How to Select the Right UV Curing Adhesive

- 5. Application Techniques for Optimal Results

- 6. Safety Considerations When Using UV Curing Adhesives

- 7. Common Issues and Solutions with UV Curing Adhesives

- 8. Frequently Asked Questions

- 9. Conclusion

1. Understanding UV Curing Adhesives

UV curing adhesives are specialty adhesives that polymerize when exposed to ultraviolet (UV) light. This process leads to a rapid curing time, usually ranging from seconds to minutes, depending on the specific adhesive formulation and curing conditions. Unlike conventional adhesives that rely on evaporation or chemical reactions, UV adhesives offer a unique advantage with their immediate setting capabilities, making them ideal for high-speed production lines.

2. Advantages of UV Curing Adhesives in Electronics

The use of UV curing adhesives in electronic applications presents numerous benefits, including:

- Speed: Instant curing allows for faster production cycles and reduced assembly times.

- Strength: Form strong bonds that withstand thermal cycling and mechanical stress.

- Clarity: Many UV adhesives are optically clear, making them suitable for applications requiring transparency.

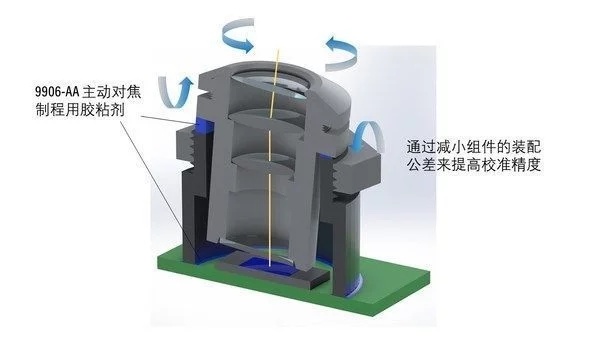

- Minimal shrinkage: Low shrinkage during curing ensures precise alignments in electronic components.

- Environmentally friendly: UV adhesives often have lower volatile organic compound (VOC) emissions compared to traditional adhesives.

3. Different Types of UV Curing Adhesives

Understanding the different types of UV curing adhesives available in the market is crucial for selecting the right one for your project. Here are the primary categories:

3.1. UV Curable Epoxy Adhesives

These adhesives offer excellent strength and durability, making them suitable for demanding electronic applications where robust bonding is essential.

3.2. UV Curable Acrylic Adhesives

Acrylic adhesives provide good adhesion on a variety of substrates and are often used for applications where flexibility and clarity are important.

3.3. UV Curable Silicone Adhesives

Ideal for applications requiring high-temperature resistance and flexibility, silicone adhesives are particularly useful in sealing and bonding processes.

4. How to Select the Right UV Curing Adhesive

Choosing the right UV curing adhesive involves several key considerations:

- Application Requirements: Assess the specific needs of your electronic project, including bonding strength, temperature resistance, and flexibility.

- Substrate Compatibility: Ensure the adhesive is compatible with the materials you are bonding. Some adhesives work better on plastics, metals, or glass.

- Curing Speed: Depending on the production environment, select an adhesive that cures quickly enough to meet your timelines without compromising bond quality.

- Environmental Resistance: Consider whether the final product will be exposed to moisture, chemicals, or extreme temperatures, and choose an adhesive designed for those conditions.

5. Application Techniques for Optimal Results

To achieve the best results with UV curing adhesives, consider the following application techniques:

5.1. Surface Preparation

Ensure that all surfaces are clean, dry, and free from contaminants. Proper surface preparation enhances adhesive bonding and performance.

5.2. Proper Dispensing

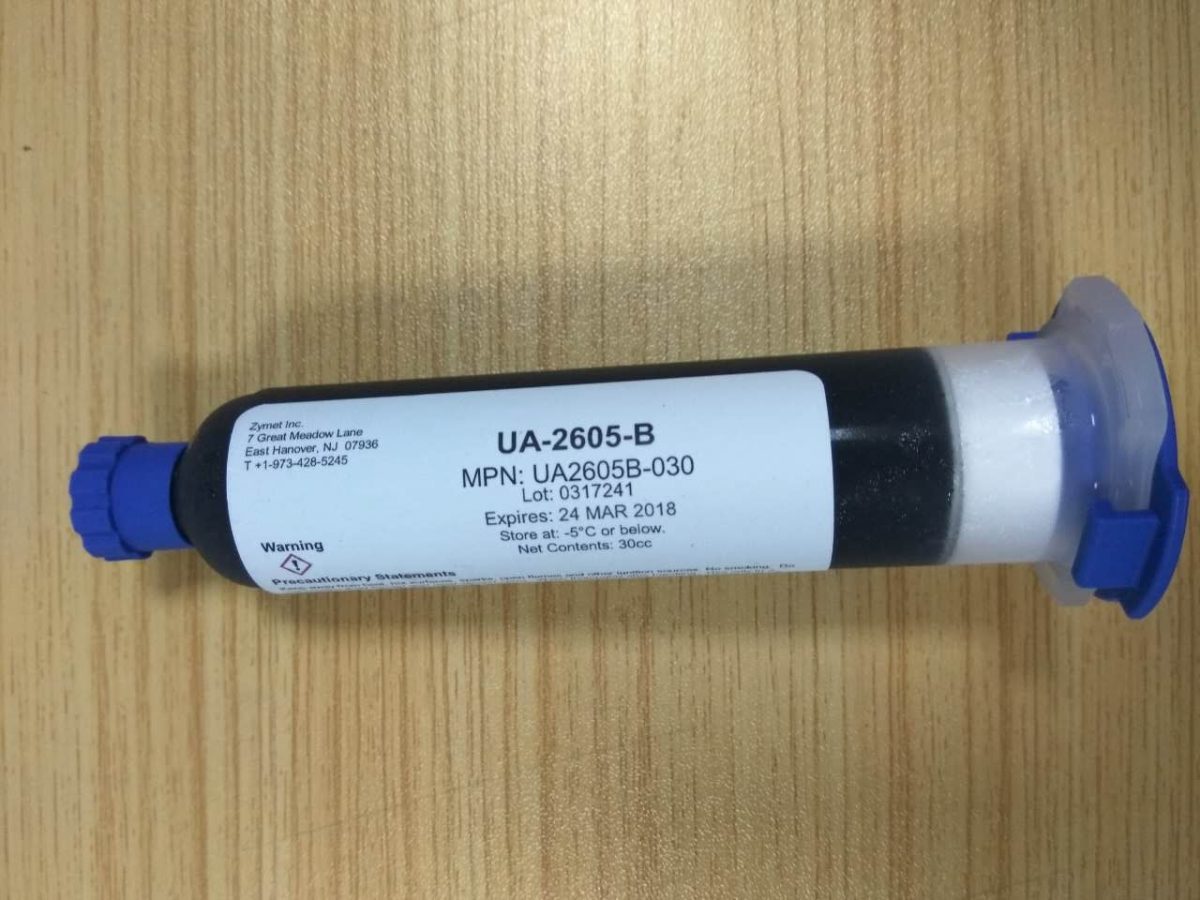

Use appropriate dispensing techniques to apply the adhesive evenly. This can include syringes, automatic dispensers, or manual application tools.

5.3. UV Exposure

Ensure the adhesive is adequately exposed to UV light for the recommended duration. Different adhesives may require varying exposure times for complete curing.

6. Safety Considerations When Using UV Curing Adhesives

While UV curing adhesives offer many advantages, safety should always be a priority. Follow these safety guidelines:

- Wear Protective Gear: Always use gloves, goggles, and protective clothing to avoid skin and eye contact with uncured adhesive.

- Ventilation: Ensure your workspace is well-ventilated to mitigate exposure to fumes during application.

- UV Light Precautions: Avoid direct exposure to UV light sources to prevent skin and eye damage.

7. Common Issues and Solutions with UV Curing Adhesives

Even experienced users may encounter challenges when working with UV curing adhesives. Here are some common issues and their solutions:

7.1. Incomplete Curing

If the adhesive is not curing properly, check the UV light intensity and exposure time. Increasing the exposure duration may help achieve complete curing.

7.2. Bond Failure

Inadequate surface preparation or incompatible substrates can lead to bond failure. Always ensure thorough cleaning and proper material selection.

7.3. Yellowing Over Time

Some UV adhesives may yellow when exposed to UV light over extended periods. Choose formulations designed for high clarity and UV stability if this is a concern.

8. Frequently Asked Questions

8.1. What is UV curing adhesive used for?

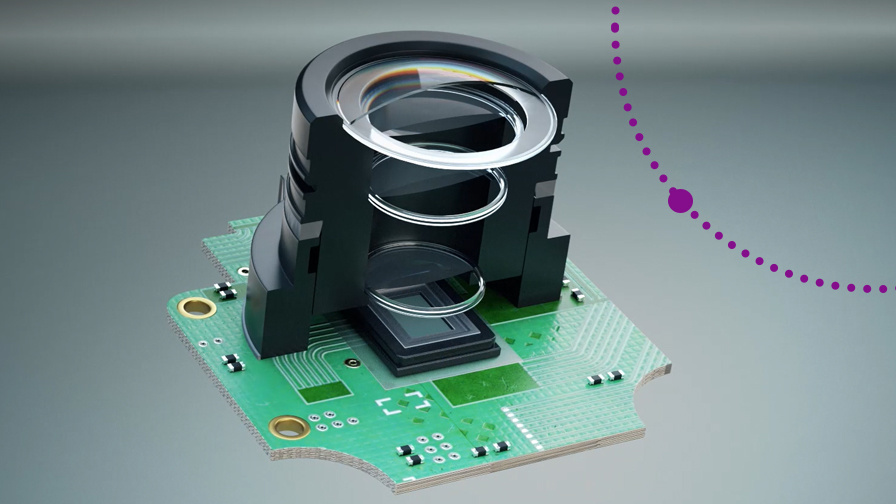

UV curing adhesives are used in various applications, including electronics, automotive, medical devices, and optical components.

8.2. How long does it take for UV curing adhesive to cure?

Curing time can range from a few seconds to several minutes, depending on the adhesive type and UV light intensity.

8.3. Can UV curing adhesives be used outdoors?

Some UV adhesives are formulated for outdoor use and are resistant to weathering. Check the product specifications for outdoor suitability.

8.4. Are UV curing adhesives safe?

When used as directed and with appropriate safety precautions, UV curing adhesives are safe. Always follow the manufacturer's guidelines.

8.5. How do I remove cured UV adhesive?

Cured UV adhesive can often be removed with solvents or mechanical means, depending on the substrate and adhesive type. Refer to the manufacturer's instructions for specific removal methods.

9. Conclusion

In conclusion, selecting the right UV curing adhesive for your electronic projects is crucial for achieving optimal performance and durability. By understanding the benefits, types, and application techniques of UV curing adhesives, you can enhance your project's success. Remember to prioritize safety and consider the specific requirements of your application to ensure you make the best choice. With the right adhesive in hand, you are well on your way to creating high-quality electronic assemblies that stand the test of time.

Related Information

China:+86 13509643690

China:+86 13509643690