UV Glue: Revolutionizing Optical Lens Assembly Processes with Advanced Adhesive Solutions

UV Glue: Revolutionizing Optical Lens Assembly Processes

In today's fast-paced technological landscape, the demand for high-quality optical lenses is skyrocketing. Industries ranging from telecommunications to healthcare rely on precision-engineered optical components. As the need for durability, efficiency, and accuracy grows, so does the significance of adhesive solutions in the assembly process. UV glue has emerged as a game changer, providing unmatched advantages in the optical lens assembly sector. This article explores the transformative impact of UV glue on optical lens assembly processes, highlighting its benefits, applications, and considerations for implementation.

Table of Contents

- 1. Understanding UV Glue: What It Is and How It Works

- 2. Benefits of UV Glue in Optical Lens Assembly

- 3. Applications of UV Glue in Various Industries

- 4. Comparison with Traditional Adhesives: Advantages and Disadvantages

- 5. Key Considerations for Using UV Glue in Lens Assembly

- 6. Environmental Impact and Sustainability of UV Adhesives

- 7. Future Trends in UV Glue Technology

- 8. Conclusion

- 9. FAQs

1. Understanding UV Glue: What It Is and How It Works

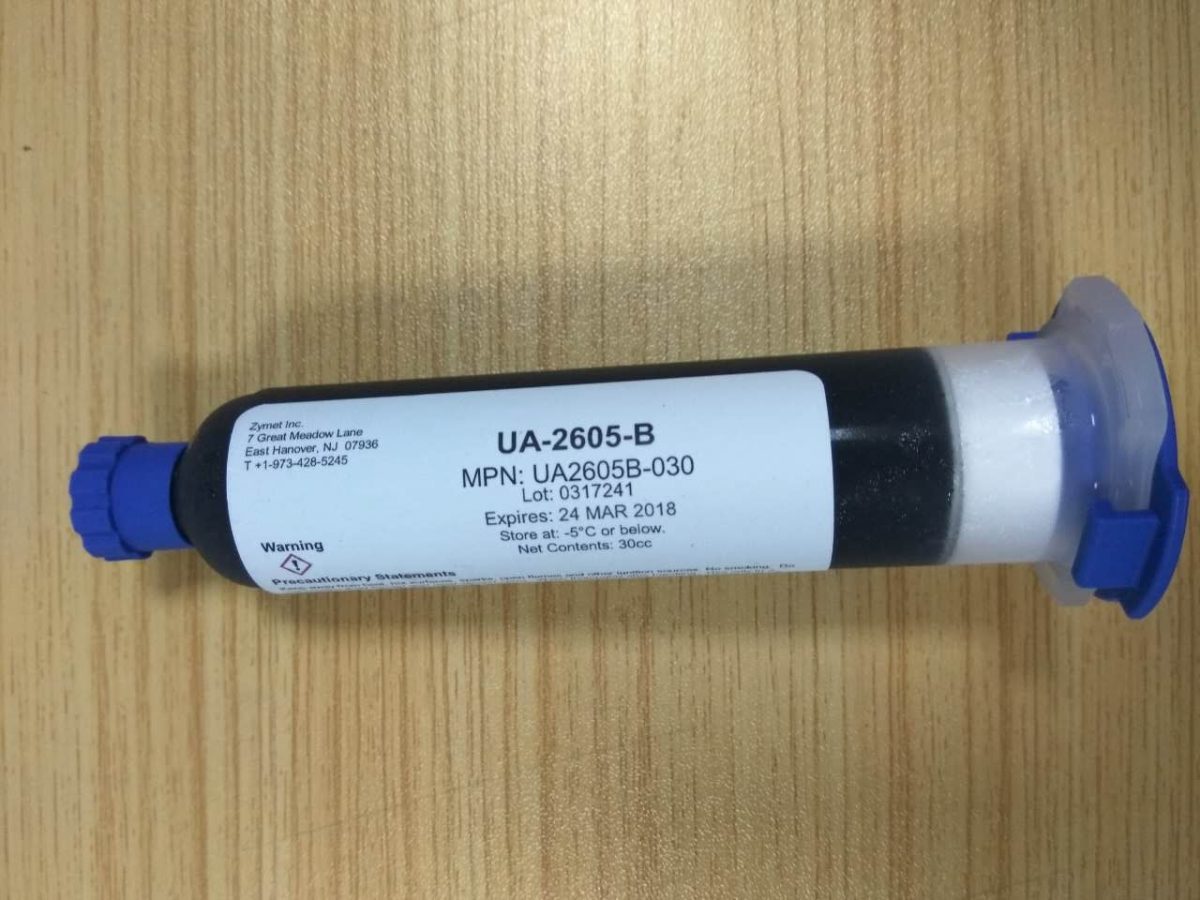

UV glue, or ultraviolet glue, is an advanced adhesive that cures and hardens when exposed to ultraviolet light. This curing process enables manufacturers to achieve immediate bonding results without the need for extended drying times typical of traditional adhesives. UV glue is formulated with photoinitiators that react to UV light, causing the adhesive to polymerize and form a strong, durable bond.

The versatility of UV glue makes it suitable for various materials, including glass, plastics, and metals. Its clarity and resistance to yellowing also make it an ideal choice for optical applications, where transparency is crucial. Understanding the chemistry and mechanisms behind UV glue allows manufacturers to leverage its benefits effectively in optical lens assembly.

2. Benefits of UV Glue in Optical Lens Assembly

The integration of UV glue in optical lens assembly processes offers an array of benefits that enhance production efficiency and product quality. Here are some key advantages:

2.1. Rapid Curing Time

One of the most significant benefits of UV glue is its rapid curing time. Traditional adhesives often require several hours to set, leading to extended production cycles. In contrast, UV glue can cure in seconds upon exposure to UV light, significantly speeding up the assembly process.

2.2. Strong and Durable Bonds

UV glue creates exceptionally strong bonds that can withstand various environmental conditions, including temperature fluctuations and moisture. This durability ensures that optical lenses maintain their integrity over time, reducing the risk of failure or degradation.

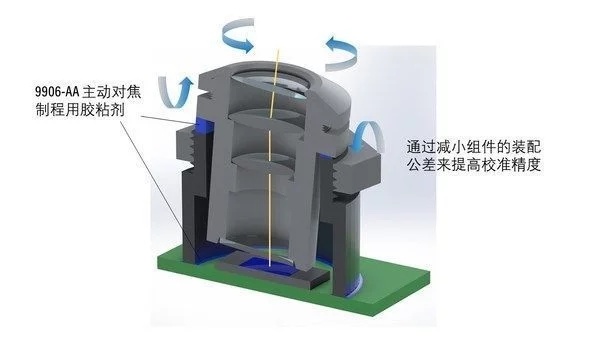

2.3. Enhanced Precision

The ability to control the curing process with UV light allows for enhanced precision in lens assembly. Manufacturers can make adjustments during the curing phase, ensuring that components align perfectly without the risk of misalignment caused by a slow-setting adhesive.

2.4. Improved Aesthetics

Many UV glues are formulated to be optically clear and resistant to yellowing over time. This characteristic is particularly advantageous in optical lens assembly, where clarity and visual quality are critical. The end product not only performs better but also looks more professional.

3. Applications of UV Glue in Various Industries

UV glue is not limited to optical lens assembly. Its versatility allows for its application across various industries, enhancing performance and efficiency in multiple contexts.

3.1. Electronics

In the electronics industry, UV glue is used for assembling components on circuit boards and securing protective covers. Its rapid curing and strong adhesion are essential for maintaining the integrity of electronic devices.

3.2. Medical Devices

Medical devices require adhesives that can withstand stringent sterilization processes. UV glue meets these requirements while providing strong bonds necessary for operational reliability.

3.3. Automotive

The automotive industry uses UV adhesives for bonding various components, including sensors and glass fixtures. The durability of UV glue ensures that these critical components remain secure throughout the vehicle's lifespan.

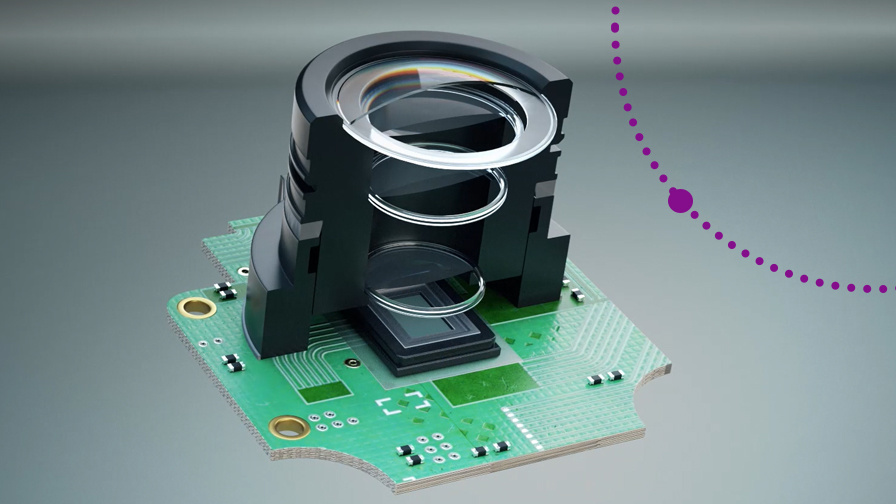

3.4. Optical Devices

Beyond lenses, UV glue plays a vital role in assembling optical devices such as microscopes and cameras, where precision and clarity are non-negotiable.

4. Comparison with Traditional Adhesives: Advantages and Disadvantages

When evaluating UV glue against traditional adhesives, it’s essential to consider both advantages and disadvantages to make informed choices.

4.1. Advantages Over Traditional Adhesives

- Speed: UV glue cures much faster than traditional adhesives, enhancing production efficiency.

- Strength: Offers superior bonding strength and durability.

- Minimal Setup: Reduces the need for clamping or holding fixtures during the curing process.

4.2. Disadvantages

- UV Sensitivity: Requires appropriate UV light exposure for curing, which may necessitate additional equipment.

- Surface Preparation: Some substrates may require specific pretreatments to optimize adhesion.

5. Key Considerations for Using UV Glue in Lens Assembly

Implementing UV glue in optical lens assembly comes with several considerations that manufacturers should be aware of to maximize its benefits:

5.1. Material Compatibility

It is crucial to ensure that the materials being bonded are compatible with UV glue. Conducting preliminary tests can help identify any potential bonding issues.

5.2. UV Light Exposure

Proper UV light exposure is essential for the effective curing of UV glue. Companies should invest in reliable UV curing systems that provide adequate wavelengths and intensities to achieve optimal results.

5.3. Environmental Conditions

Temperature and humidity can affect the performance of UV adhesives. Maintaining controlled environmental conditions during the assembly process can enhance bond quality.

5.4. Safety Precautions

Utilizing UV glue requires adherence to safety protocols, particularly regarding UV light exposure. Protective equipment should be worn to safeguard workers from potential harm.

6. Environmental Impact and Sustainability of UV Adhesives

As industries strive for sustainability, the environmental impact of materials used in manufacturing processes is under scrutiny. UV adhesives are generally considered more environmentally friendly compared to traditional solvents and adhesives, mainly due to their low volatile organic compound (VOC) emissions.

Nonetheless, manufacturers must evaluate the entire lifecycle of UV adhesives, from production to disposal, to ensure they align with sustainability goals. Many suppliers are now offering eco-friendly formulations, paving the way for a greener future in adhesive technologies.

7. Future Trends in UV Glue Technology

The future of UV adhesive technology holds immense potential. Innovations in formulations aim to enhance performance, such as:

7.1. New Formulations for Enhanced Performance

Research and development are focused on creating UV glues with improved adhesion properties and quicker curing times, broadening their applicability in various industries.

7.2. Smart Adhesives

Emerging smart adhesive technologies incorporate sensors that can indicate bond integrity or exposure to environmental factors, providing real-time data for manufacturers.

7.3. Increased Customization

There is a growing trend toward customizable adhesive solutions tailored to specific applications, allowing manufacturers to select the ideal glue for their unique needs.

8. Conclusion

UV glue is undeniably a game changer in the realm of optical lens assembly. Its rapid curing time, strong adhesion, and aesthetic advantages make it an invaluable asset for manufacturers aiming to improve efficiency and quality. As industries continue to evolve, the potential for UV glue technology to lead the way in adhesive solutions remains remarkable. By understanding the benefits, applications, and key considerations associated with UV glue, manufacturers can harness its advantages to streamline their assembly processes and stay ahead in a competitive market.

9. FAQs

What is UV glue, and how does it work?

UV glue is an adhesive that cures when exposed to ultraviolet light. The photoinitiators in the glue react to UV light, causing the adhesive to harden and form a strong bond between materials.

What are the main advantages of using UV glue in optical lens assembly?

Key advantages include rapid curing time, strong and durable bonds, enhanced precision during assembly, and improved aesthetics through optical clarity.

Can UV glue be used on all materials?

While UV glue is versatile, it is essential to ensure compatibility with the materials being bonded. Pre-testing is advisable to confirm optimal adhesion.

Are there any safety concerns when using UV glue?

Yes, UV glue requires careful handling due to UV light exposure. Protective equipment should be worn, and proper safety protocols should be followed.

How does UV glue compare to traditional adhesives?

UV glue offers advantages such as quicker curing times and stronger bonds compared to traditional adhesives. However, it may require specific curing equipment and surface preparation.

Related Information

China:+86 13509643690

China:+86 13509643690