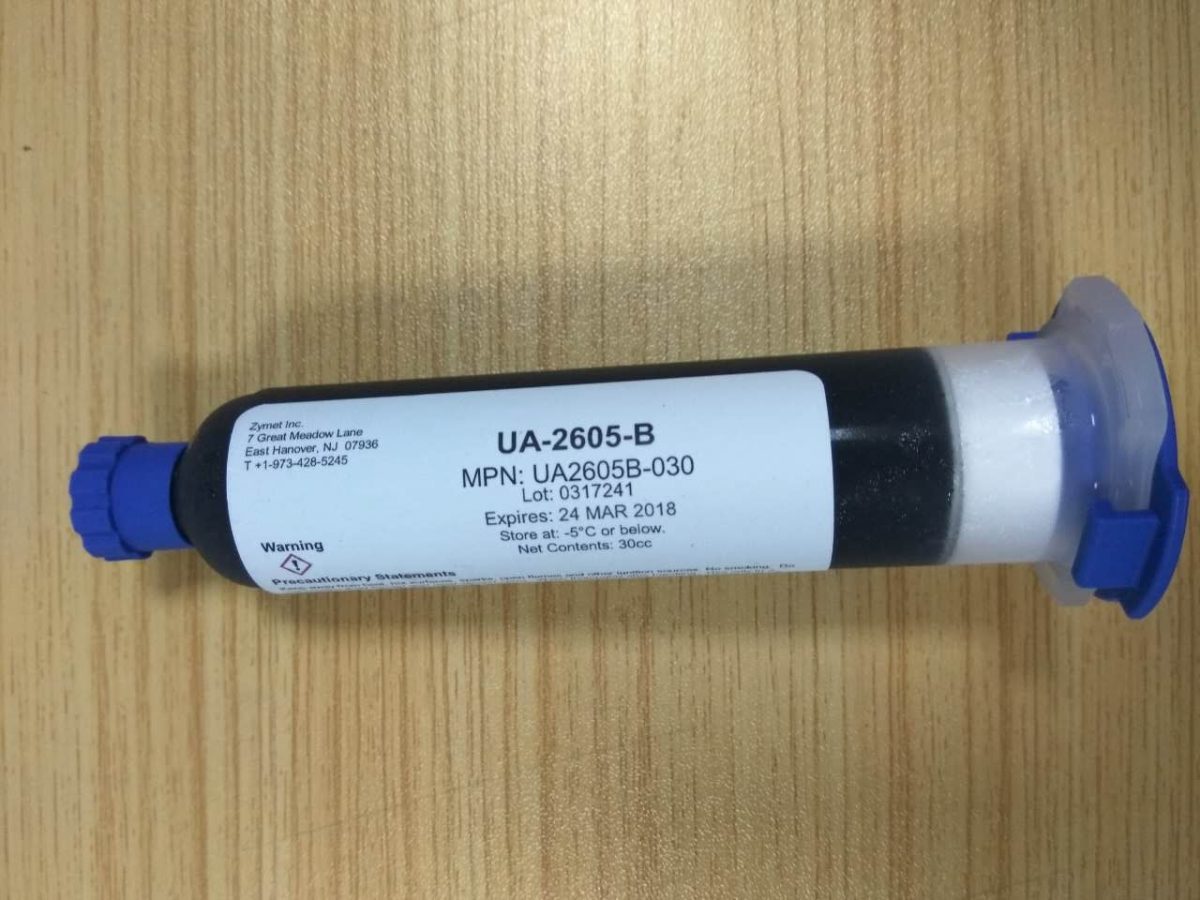

Medical grade UV adhesive is a specialized adhesive formulated to meet the stringent requirements of the medical and healthcare industries. This type of adhesive is designed to bond a variety of substrates, including glass, plastics, and metals, and is particularly valued for its fast curing properties when exposed to ultraviolet (UV) light. Understanding the unique attributes and applications of medical grade UV adhesive can provide significant advantages in various settings.

One of the primary benefits of medical grade UV adhesive is its rapid curing time. When exposed to UV light, these adhesives can cure within seconds, allowing for faster production processes in medical device manufacturing. This efficiency can be crucial when time is of the essence, particularly in environments where rapid prototyping and assembly are essential.

Another key characteristic of medical grade UV adhesive is its biocompatibility. These adhesives are formulated to comply with regulatory standards, ensuring that they do not pose any risk to patient safety. This makes them ideal for use in applications such as wound dressings, surgical devices, and dental materials. The ability to create strong bonds without compromising safety is a major factor in their growing popularity in the medical field.

In addition to its curing speed and biocompatibility, medical grade UV adhesive offers excellent resistance to moisture and temperature variations. This durability is essential when considering the diverse environments that medical devices may encounter, from sterilization processes to varying patient conditions. The adhesive’s ability to maintain bond integrity under such conditions makes it a reliable choice for critical applications.

Moreover, medical grade UV adhesive allows for minimal surface preparation, enabling manufacturers to save time and resources. Unlike traditional adhesives, which may require extensive cleaning or priming, UV adhesives can often be applied directly to clean surfaces, streamlining the assembly process. This ease of use can lead to increased efficiency and reduced operational costs.

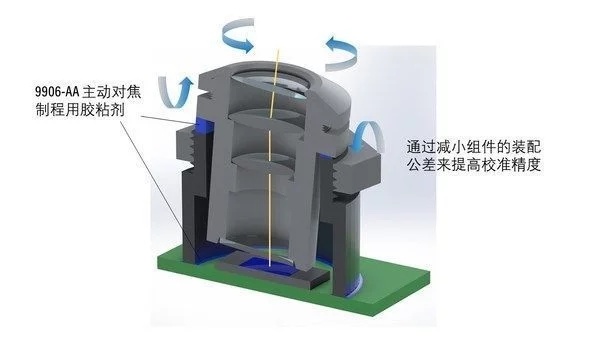

The versatility of medical grade UV adhesive also extends to its applications. Beyond bonding medical devices, it is commonly used in the production of optical devices, sensors, and electronic components where precision and durability are paramount. Its adaptability to various substrates makes it a valuable resource in numerous sectors beyond healthcare.

In conclusion, medical grade UV adhesive represents a significant advancement in adhesive technology for the medical and healthcare industries. With its rapid curing, biocompatibility, moisture resistance, and versatility, it stands out as a critical solution for manufacturers looking to enhance their production processes while ensuring patient safety. Understanding its benefits and applications can empower businesses to make informed choices that align with their operational needs and compliance requirements.

One of the primary benefits of medical grade UV adhesive is its rapid curing time. When exposed to UV light, these adhesives can cure within seconds, allowing for faster production processes in medical device manufacturing. This efficiency can be crucial when time is of the essence, particularly in environments where rapid prototyping and assembly are essential.

Another key characteristic of medical grade UV adhesive is its biocompatibility. These adhesives are formulated to comply with regulatory standards, ensuring that they do not pose any risk to patient safety. This makes them ideal for use in applications such as wound dressings, surgical devices, and dental materials. The ability to create strong bonds without compromising safety is a major factor in their growing popularity in the medical field.

In addition to its curing speed and biocompatibility, medical grade UV adhesive offers excellent resistance to moisture and temperature variations. This durability is essential when considering the diverse environments that medical devices may encounter, from sterilization processes to varying patient conditions. The adhesive’s ability to maintain bond integrity under such conditions makes it a reliable choice for critical applications.

Moreover, medical grade UV adhesive allows for minimal surface preparation, enabling manufacturers to save time and resources. Unlike traditional adhesives, which may require extensive cleaning or priming, UV adhesives can often be applied directly to clean surfaces, streamlining the assembly process. This ease of use can lead to increased efficiency and reduced operational costs.

The versatility of medical grade UV adhesive also extends to its applications. Beyond bonding medical devices, it is commonly used in the production of optical devices, sensors, and electronic components where precision and durability are paramount. Its adaptability to various substrates makes it a valuable resource in numerous sectors beyond healthcare.

In conclusion, medical grade UV adhesive represents a significant advancement in adhesive technology for the medical and healthcare industries. With its rapid curing, biocompatibility, moisture resistance, and versatility, it stands out as a critical solution for manufacturers looking to enhance their production processes while ensuring patient safety. Understanding its benefits and applications can empower businesses to make informed choices that align with their operational needs and compliance requirements.

Related Information

China:+86 13509643690

China:+86 13509643690