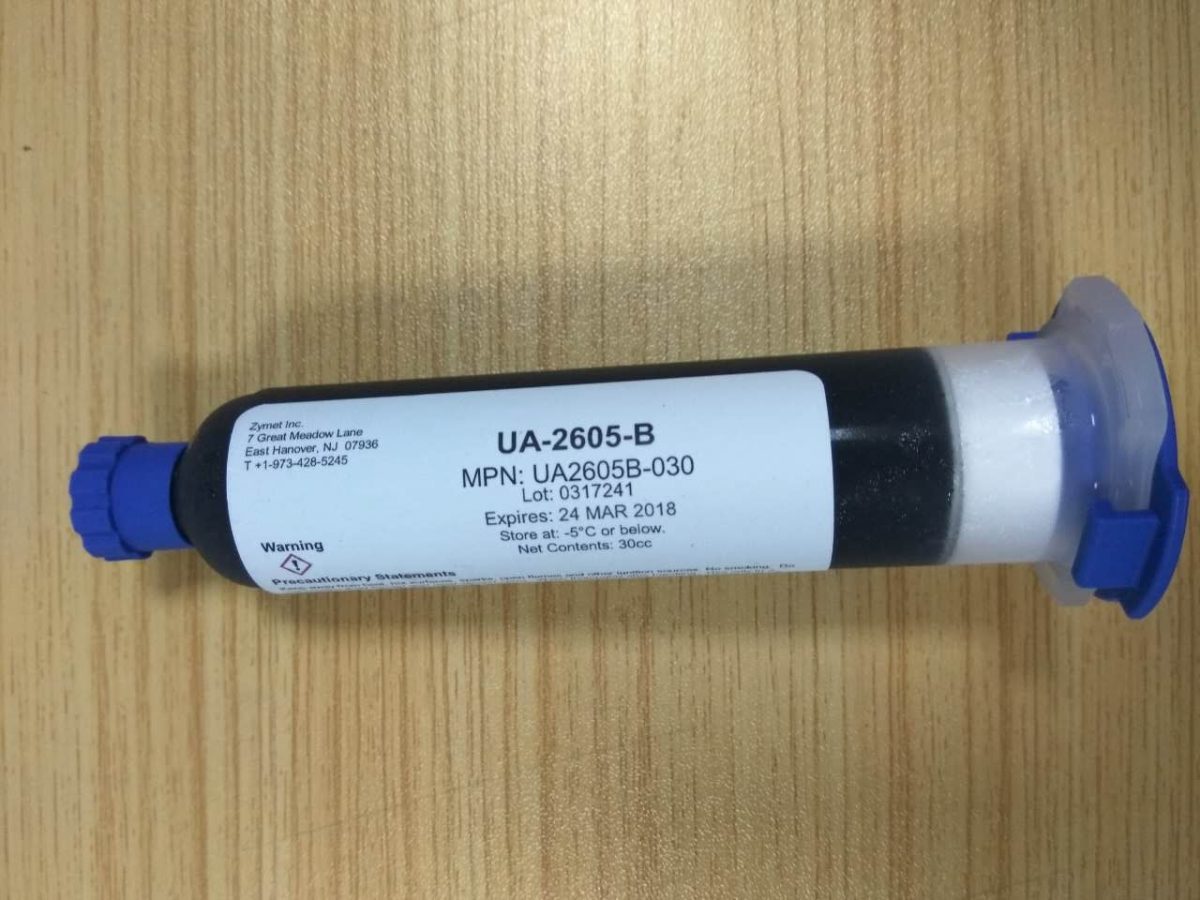

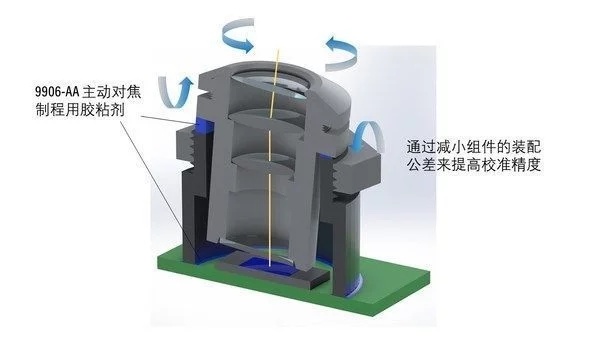

Low shrinkage epoxy resin adhesives are engineered formulations designed to minimize dimensional changes during the curing process. Traditional adhesives often experience significant shrinkage, which can lead to issues such as misalignment, reduced bond strength, and compromised performance in applications. In contrast, low shrinkage epoxy resins are formulated to maintain their integrity, ensuring a more stable bond that withstands various environmental conditions.

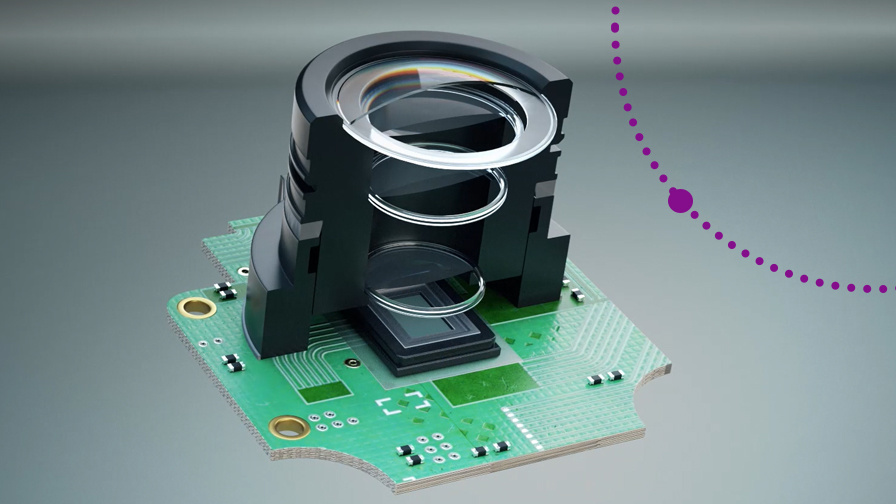

One of the critical benefits of low shrinkage epoxy resin adhesives is their superior adhesion to a wide range of substrates. They provide excellent bonding to materials such as metals, ceramics, glass, and many plastics. This versatility makes them ideal for use in diverse industries, including automotive, aerospace, electronics, and construction. Professionals often choose these adhesives for applications requiring high strength and durability, where traditional adhesives may fail.

Additionally, low shrinkage epoxy resins offer enhanced thermal and chemical resistance. This characteristic is particularly important in environments exposed to fluctuating temperatures or aggressive chemicals. As a result, using these adhesives can significantly extend the lifespan of bonded assemblies, reducing maintenance costs and downtime.

The curing process of low shrinkage epoxy resin adhesives is also noteworthy. These adhesives typically cure at room temperature, though some formulations may allow for accelerated curing with heat. The controlled cure minimizes stress on the bonded materials, which is crucial in applications where precision and reliability are paramount.

Another significant advantage is the aesthetic benefits. Low shrinkage epoxy adhesives tend to have a clear or translucent appearance once cured, making them suitable for applications where visual clarity is essential, such as in electronic components and decorative finishes. Their smooth finish also allows for easy post-processing, such as sanding or painting, enabling a seamless integration into the final product.

In terms of application, low shrinkage epoxy resin adhesives are widely used in manufacturing processes such as potting and encapsulation, where protecting sensitive components is essential. They are also ideal for structural bonding in load-bearing applications, where the integrity of the bond is critical to the overall performance of the assembly.

In conclusion, low shrinkage epoxy resin adhesives offer a compelling solution for various bonding challenges faced by professionals across multiple industries. Their unique properties, including minimal shrinkage, excellent adhesion, thermal resistance, and aesthetic advantages, make them an essential choice for high-performance applications. As the demand for advanced adhesive solutions continues to grow, understanding the capabilities and applications of low shrinkage epoxy resin adhesives becomes increasingly vital for success in the field.

One of the critical benefits of low shrinkage epoxy resin adhesives is their superior adhesion to a wide range of substrates. They provide excellent bonding to materials such as metals, ceramics, glass, and many plastics. This versatility makes them ideal for use in diverse industries, including automotive, aerospace, electronics, and construction. Professionals often choose these adhesives for applications requiring high strength and durability, where traditional adhesives may fail.

Additionally, low shrinkage epoxy resins offer enhanced thermal and chemical resistance. This characteristic is particularly important in environments exposed to fluctuating temperatures or aggressive chemicals. As a result, using these adhesives can significantly extend the lifespan of bonded assemblies, reducing maintenance costs and downtime.

The curing process of low shrinkage epoxy resin adhesives is also noteworthy. These adhesives typically cure at room temperature, though some formulations may allow for accelerated curing with heat. The controlled cure minimizes stress on the bonded materials, which is crucial in applications where precision and reliability are paramount.

Another significant advantage is the aesthetic benefits. Low shrinkage epoxy adhesives tend to have a clear or translucent appearance once cured, making them suitable for applications where visual clarity is essential, such as in electronic components and decorative finishes. Their smooth finish also allows for easy post-processing, such as sanding or painting, enabling a seamless integration into the final product.

In terms of application, low shrinkage epoxy resin adhesives are widely used in manufacturing processes such as potting and encapsulation, where protecting sensitive components is essential. They are also ideal for structural bonding in load-bearing applications, where the integrity of the bond is critical to the overall performance of the assembly.

In conclusion, low shrinkage epoxy resin adhesives offer a compelling solution for various bonding challenges faced by professionals across multiple industries. Their unique properties, including minimal shrinkage, excellent adhesion, thermal resistance, and aesthetic advantages, make them an essential choice for high-performance applications. As the demand for advanced adhesive solutions continues to grow, understanding the capabilities and applications of low shrinkage epoxy resin adhesives becomes increasingly vital for success in the field.

Related Information

China:+86 13509643690

China:+86 13509643690