How Silicone Adhesive Sealants Improve Waterproofing in Electronics

Introduction to Silicone Adhesive Sealants

Silicone adhesive sealants have emerged as a critical material in the realm of electronics, particularly for enhancing waterproofing. Their unique properties make them indispensable in various applications, from consumer electronics to industrial machinery. In this article, we will delve deeply into how these adhesives function and why they are preferred for waterproofing electronic applications.

The Science Behind Silicone Adhesives

Silicone adhesives differ from traditional adhesives due to their unique chemical structure, which consists of silicon-oxygen backbones. This composition provides several advantages that are crucial for waterproofing:

Elasticity and Flexibility

One of the standout features of silicone adhesives is their exceptional elasticity. This flexibility allows them to accommodate the thermal expansion and contraction of electronic components without cracking or losing adhesion. This attribute is especially important in environments where temperature fluctuations are common.

Resistance to Environmental Factors

Silicone adhesives boast superior resistance to moisture, UV radiation, and temperature extremes. This resistance makes them ideal for outdoor electronic devices that must withstand harsh conditions. Their stability ensures that sealants maintain their integrity over time, providing long-lasting waterproofing.

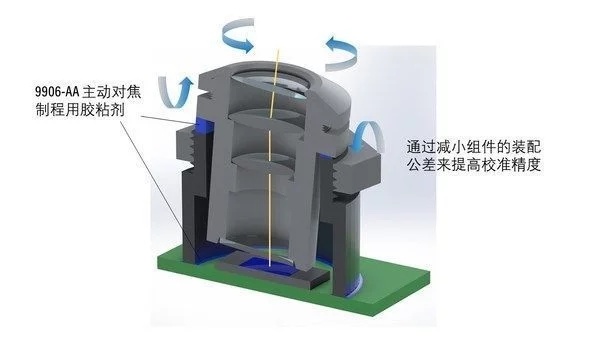

Adhesion Properties

The adhesion properties of silicone sealants are remarkable. They bond well to various substrates, including metals, plastics, and glass, commonly found in electronic devices. This versatility allows manufacturers to utilize silicone adhesives across a wide range of applications without worry about compatibility.

Applications of Silicone Adhesive Sealants in Electronics

Silicone adhesives are employed in numerous electronic applications, including:

Consumer Electronics

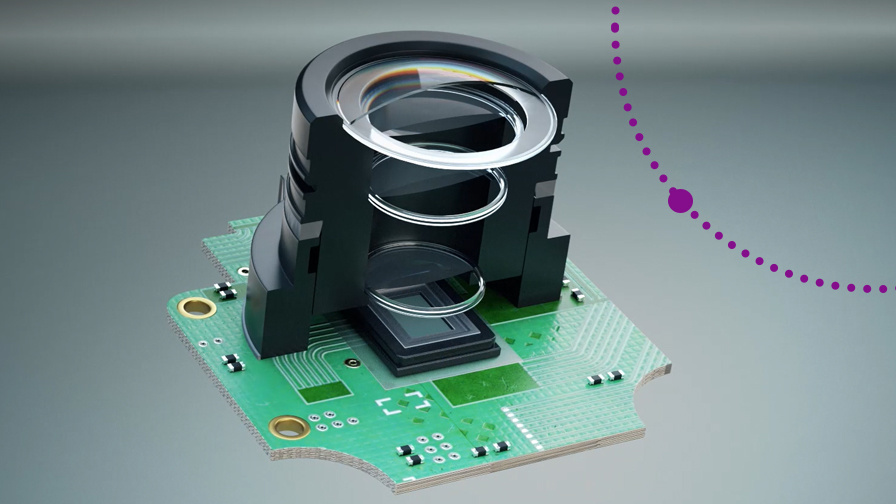

In consumer electronics, such as smartphones, tablets, and laptops, silicone sealants are used to protect sensitive components from moisture intrusion. Their application in these devices extends the lifespan and ensures reliability, especially in humid conditions.

Industrial Equipment

Heavy machinery and industrial equipment often operate in environments where exposure to water, dust, and chemicals is inevitable. Silicone adhesive sealants are extensively used to waterproof critical components, enhancing the durability and performance of the equipment.

Automotive Electronics

The automotive industry has greatly benefited from silicone adhesive sealants. These materials are used to protect electronic control units, sensors, and wiring harnesses from moisture and contaminants, ensuring the reliability of safety features and overall vehicle performance.

Benefits of Using Silicone Sealants for Waterproofing

The advantages of employing silicone adhesive sealants in waterproofing electronics are profound. Here are some key benefits:

Longevity and Durability

Silicone adhesives are known for their longevity. When properly applied, they can provide waterproofing solutions that last for years, reducing the need for frequent repairs or replacements. This durability is invaluable in cost-sensitive industries.

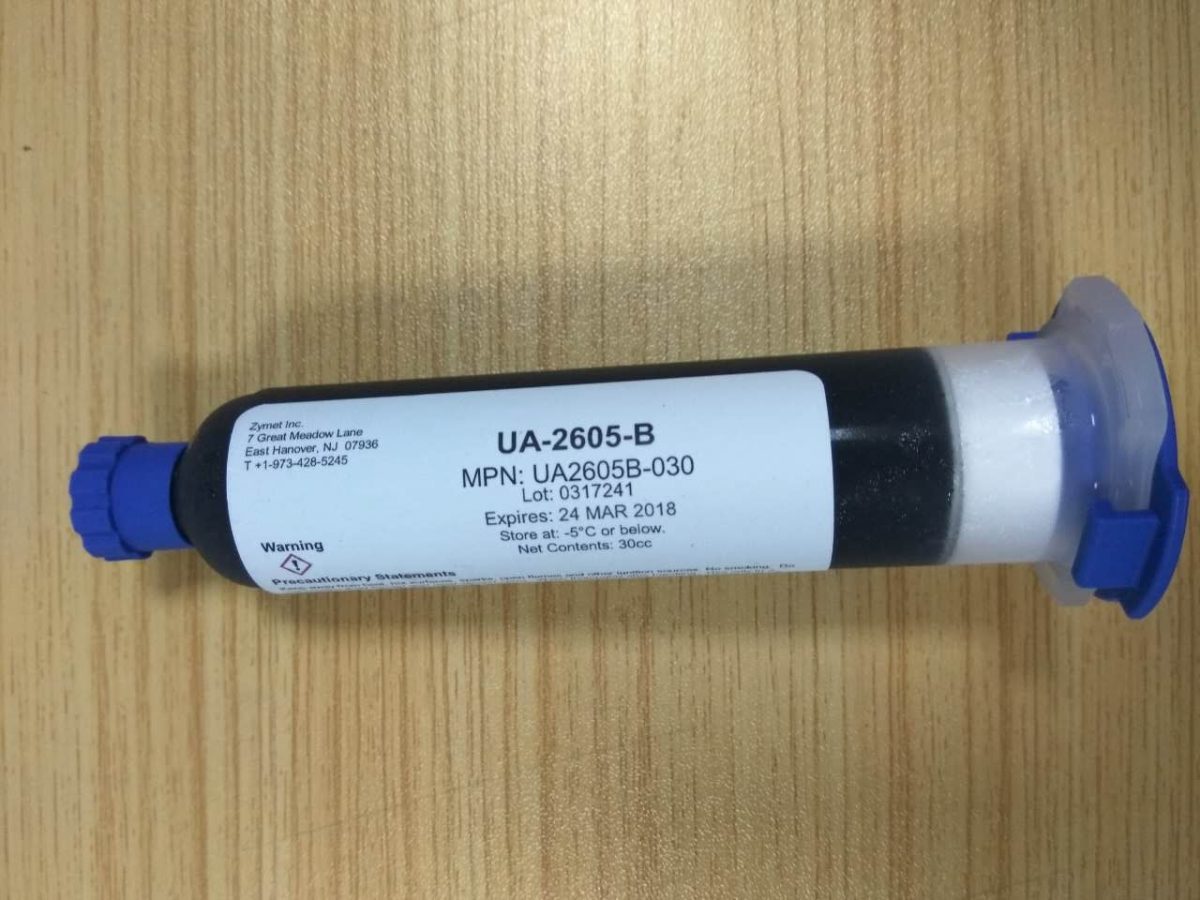

Ease of Application

Silicone adhesives can be easily applied in various forms, including tubes, cartridges, and bulk containers. This versatility simplifies the application process and makes it accessible for both manufacturers and DIY enthusiasts.

Non-Toxic and Environmentally Friendly

Most silicone adhesive sealants are non-toxic and environmentally friendly. They do not release harmful fumes during application, making them suitable for indoor use and in products intended for consumer markets.

How to Choose the Right Silicone Adhesive Sealant

Selecting the appropriate silicone adhesive sealant for waterproofing electronics involves several considerations:

Specific Application Requirements

Identify the specific needs of your application. Consider factors such as temperature range, moisture exposure, and the materials being bonded. Different formulations of silicone adhesives cater to different requirements.

Viscosity and Curing Time

Evaluate the viscosity of the silicone adhesive. Thicker adhesives may be better for vertical applications, while thinner ones might be suitable for intricate designs. Additionally, consider the curing time, especially for high-volume production.

Certifications and Standards

Ensure that the selected silicone adhesive meets relevant industry standards and certifications. This is particularly crucial for electronics that will be used in critical applications, such as medical devices or aerospace components.

Best Practices for Applying Silicone Adhesive Sealants

For optimum performance, it’s essential to follow best practices while applying silicone adhesive sealants:

Surface Preparation

Ensure that the surfaces being bonded are clean, dry, and free from contaminants such as oil, dust, or moisture. Proper preparation enhances adhesion and effectiveness.

Application Technique

Apply the silicone adhesive evenly and avoid excessive application, which can lead to oozing and mess. Use a caulking gun or applicator for precise application, ensuring that the sealant fills gaps without overfilling.

Curing Conditions

Allow the adhesive to cure under the recommended conditions specified by the manufacturer. This may include temperature and humidity levels, which can affect the curing process and overall performance.

Challenges and Considerations

While silicone adhesive sealants offer numerous advantages, there are challenges to consider:

Adhesion to Certain Plastics

Some plastics may not bond well with silicone adhesives. It may be necessary to conduct adhesion tests or use primers to enhance bonding strength.

Over-siliconing

Using too much silicone can lead to problems such as poor aesthetics and inefficient sealing. It’s crucial to find a balance in application to ensure effectiveness without excess.

Cost Factors

Although silicone adhesives can be more expensive than traditional adhesives, their long-term benefits often outweigh the initial costs. Evaluating the total cost of ownership is essential in determining the value of silicone sealants.

Conclusion

Silicone adhesive sealants play a vital role in enhancing waterproofing in electronics, providing exceptional durability, resistance to environmental factors, and ease of application. Their versatility makes them suitable for a wide range of applications, from consumer devices to industrial machinery and automotive electronics. As technology continues to advance and the demand for reliable waterproofing solutions grows, silicone adhesive sealants will remain a critical component in the manufacturing of electronic devices. By understanding their properties and best practices for application, manufacturers can ensure that their products meet the highest standards of quality and reliability.

FAQs

1. What are silicone adhesive sealants primarily used for in electronics?

Silicone adhesive sealants are primarily used for waterproofing electronic components, ensuring protection against moisture, dust, and other environmental factors.

2. How do silicone adhesives compare to other types of adhesives for waterproofing?

Silicone adhesives offer superior flexibility, temperature resistance, and adhesion to various substrates compared to many traditional adhesives, making them preferable for waterproofing applications.

3. Can silicone adhesive sealants be used in high-temperature applications?

Yes, silicone adhesives have excellent thermal stability and can withstand high temperatures, making them suitable for applications where heat resistance is required.

4. How should I store silicone adhesive sealants?

Silicone adhesive sealants should be stored in a cool, dry place, away from direct sunlight and extreme temperatures, to maintain their effectiveness.

5. Are silicone adhesives safe for use in consumer electronics?

Most silicone adhesive sealants are non-toxic and safe for use in consumer electronics, but it is essential to check the manufacturer's specifications and certifications for safety compliance.

Related Information

China:+86 13509643690

China:+86 13509643690