Finding the Right Instant Adhesive for Your Plastic and Rubber Needs

Table of Contents

- 1. Introduction to Instant Adhesives

- 2. Types of Instant Adhesives for Plastic and Rubber

- 3. Criteria for Selecting the Right Adhesive

- 4. Application Techniques for Instant Adhesives

- 5. Common Applications of Instant Adhesives in Plastic and Rubber

- 6. Advantages and Disadvantages of Instant Adhesives

- 7. Safety Considerations When Using Instant Adhesives

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Instant Adhesives

In the realm of bonding agents, **instant adhesives** stand out due to their rapid curing properties and versatility. Particularly for applications involving plastic and rubber, these adhesives provide a reliable solution where traditional adhesives might fall short. Understanding the nuances of these adhesives is essential for achieving the best results in your projects.

2. Types of Instant Adhesives for Plastic and Rubber

Choosing the right **instant adhesive** requires knowledge of the various types available. Below, we detail the most common categories of instant adhesives that are suitable for bonding plastic and rubber.

Cyanocrylate Adhesives

Cyanocrylate, often referred to as "super glue," is the most widely recognized type of instant adhesive. It cures quickly upon contact with moisture in the air, forming a strong bond.

Epoxy Adhesives

Epoxy adhesives consist of a resin and a hardener. While they may take longer to set than cyanocrylate, they offer exceptional strength and durability, making them ideal for high-stress applications.

Polyurethane Adhesives

Polyurethane adhesives provide flexibility and resistance to moisture, making them suitable for rubber and plastic applications. This type of adhesive is perfect for projects requiring a strong yet flexible bond.

MS Polymer Adhesives

Modified silane (MS) polymer adhesives are versatile, offering high strength and flexibility. They are often used in construction and automotive applications where durability is paramount.

3. Criteria for Selecting the Right Adhesive

When selecting an instant adhesive for plastic and rubber, several factors should be taken into account:

Material Compatibility

Different plastics and rubbers have unique properties, and not all adhesives work well with every material. Always check the manufacturer's recommendations for compatibility to ensure optimal bonding.

Bond Strength

Depending on your application, you may require varying levels of bond strength. Evaluate the tensile and shearing strength of the adhesive to match your project requirements.

Curing Time

Curing time is critical, especially in time-sensitive projects. While some adhesives cure in seconds, others may take hours or days. Choose an adhesive that fits your timeline.

Environmental Resistance

Consider the environmental conditions your bond will face. Factors such as temperature fluctuations, exposure to moisture, and UV light can significantly affect adhesive performance.

Ease of Application

Some adhesives are easier to apply than others. Consider using precision applicators for small jobs or those that require detailed work.

4. Application Techniques for Instant Adhesives

Applying instant adhesives correctly is crucial for achieving a strong bond. Here are some best practices:

Surface Preparation

Start by cleaning the surfaces to be bonded. Remove any dirt, grease, or dust for optimal adhesion. For plastics, consider lightly sanding the surface to enhance bonding.

Applying the Adhesive

Apply a thin, even layer of adhesive to one surface. Avoid over-application, as excess adhesive can lead to weaker bonds and longer curing times.

Joining the Surfaces

Quickly press the surfaces together, ensuring they are aligned properly. Hold them in place for the recommended setting time to allow the adhesive to bond effectively.

Post-Application Care

After application, keep the bonded surfaces undisturbed for the recommended curing time. This will ensure the adhesive achieves its full strength.

5. Common Applications of Instant Adhesives in Plastic and Rubber

Instant adhesives are used in various industries due to their versatility. Here are some common applications:

Automotive Industry

In automotive manufacturing, instant adhesives are used for bonding plastic components, rubber seals, and even electronic parts due to their quick setting time and durability.

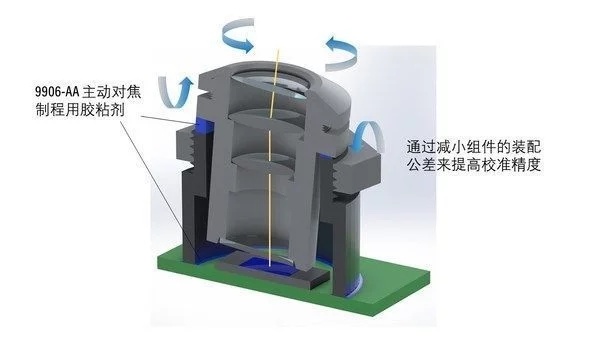

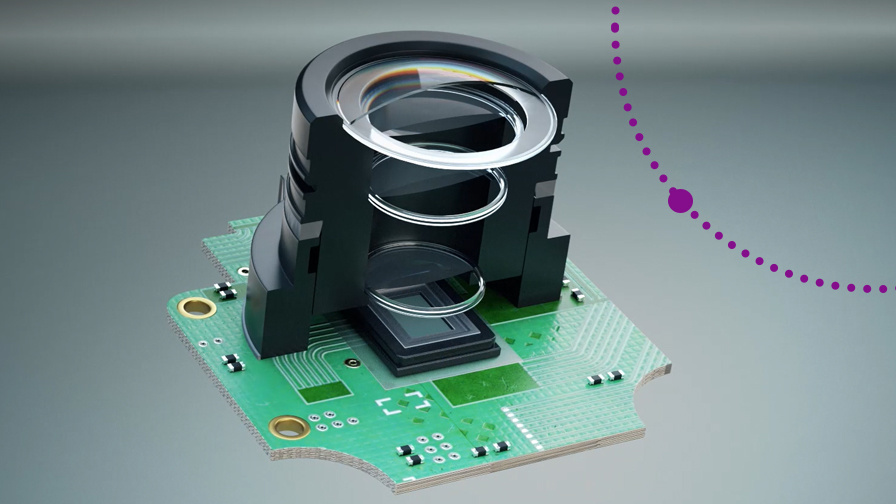

Consumer Electronics

Instant adhesives are crucial in consumer electronics for bonding components and securing casings. Their ability to bond dissimilar materials makes them invaluable in this sector.

Medical Devices

In the medical field, instant adhesives are used for securing sutures, bonding medical devices, and even in prosthetics, offering strength and reliability.

Arts and Crafts

For hobbyists and artists, instant adhesives provide quick fixes and permanent bonds, making them a staple in crafting projects involving plastic and rubber.

6. Advantages and Disadvantages of Instant Adhesives

Understanding the pros and cons of instant adhesives can help you make an informed decision.

Advantages

- **Fast Setting Time**: Instant adhesives cure quickly, allowing for rapid project completion.

- **Versatility**: They can bond a wide variety of materials, including plastics, rubbers, metals, and ceramics.

- **High Strength**: Most instant adhesives provide a strong bond, often exceeding the strength of the materials they join.

Disadvantages

- **Limited Gap Filling**: Instant adhesives may not perform well in applications where there are significant gaps between surfaces.

- **Brittleness**: Some types may become brittle over time, especially when exposed to extreme temperatures.

- **Sensitivity to Moisture**: Some instant adhesives may require specific humidity levels for optimal curing.

7. Safety Considerations When Using Instant Adhesives

Safety should always be a priority when working with adhesives. Here are some essential safety tips:

Use Protective Gear

Always wear gloves and safety goggles to protect your skin and eyes from accidental splashes.

Ventilation

Ensure you are working in a well-ventilated area. Many adhesives emit fumes that can be harmful if inhaled.

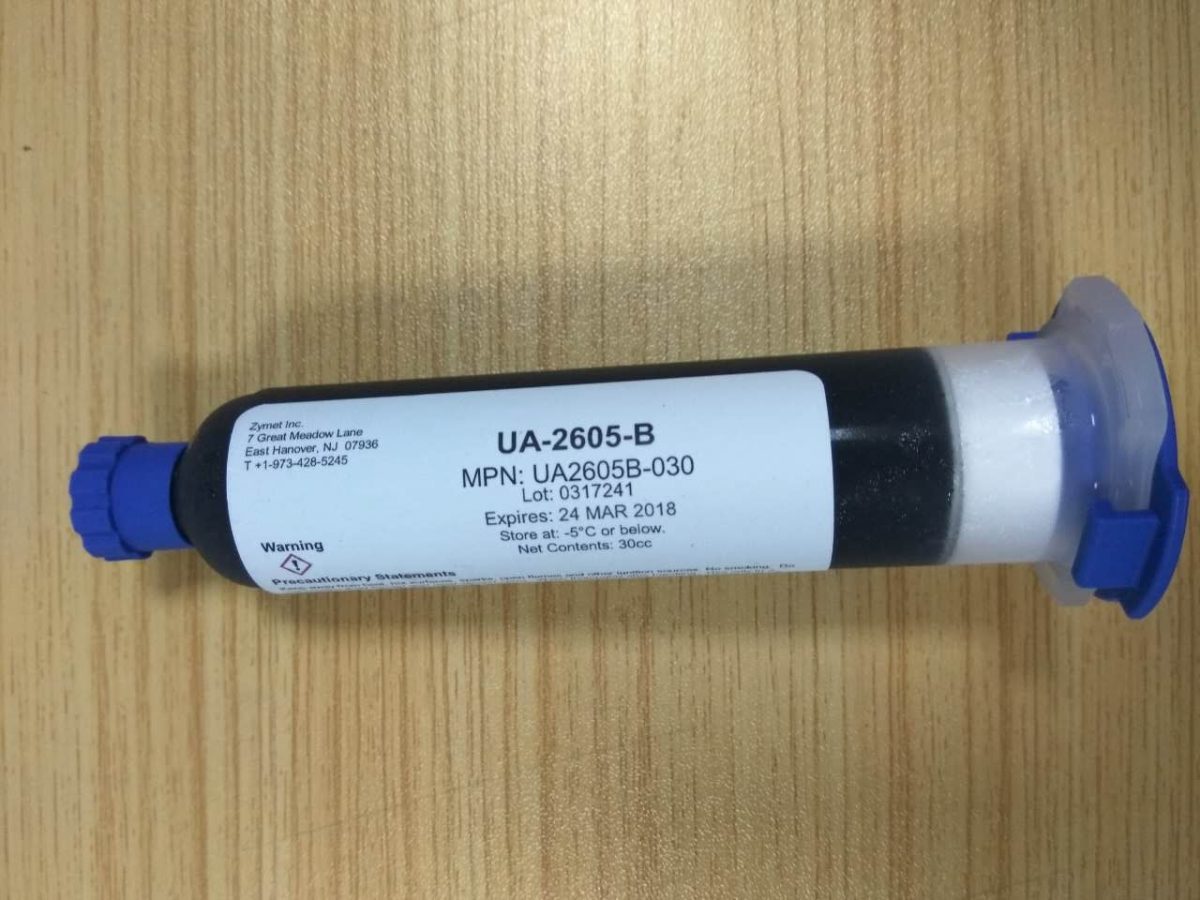

Storage

Store adhesives in a cool, dry place away from direct sunlight. Ensure they are out of reach of children and pets.

Read Labels

Be sure to read labels and safety data sheets for specific handling and storage instructions.

8. Frequently Asked Questions

1. What is the best instant adhesive for plastic and rubber?

The best instant adhesive depends on the specific types of plastic and rubber you are working with. Cyanocrylate adhesives are popular for quick fixes, while epoxy and polyurethane adhesives are better for durability.

2. How do I prepare surfaces for bonding?

Clean the surfaces with isopropyl alcohol or soap and water. For plastics, lightly sanding the surface can improve adhesion.

3. Can instant adhesives be used on wet surfaces?

Most instant adhesives require dry surfaces for optimal bonding. However, some products are specifically designed for wet environments.

4. How long does it take for instant adhesive to cure?

Curing times vary by product. Some cyanocrylate adhesives can set in seconds, while epoxy adhesives may take hours or even days to reach full strength.

5. Is it safe to use instant adhesive on food-related items?

Not all instant adhesives are food-safe. Always check the manufacturer’s specifications before using any adhesive on items that will come into contact with food.

9. Conclusion

Finding the right instant adhesive for your plastic and rubber needs requires understanding the types available, selecting based on compatibility and application, and applying them correctly. By considering the factors outlined in this guide, you can achieve strong, durable bonds for a variety of projects. Always prioritize safety and be informed about the materials you are working with to ensure the best results. With the right knowledge and tools, you can navigate the world of instant adhesives with confidence, transforming your ideas into reality.

Related Information

China:+86 13509643690

China:+86 13509643690